Home / All / Custom Silicone Rubber Parts / Custom Silicone Case /

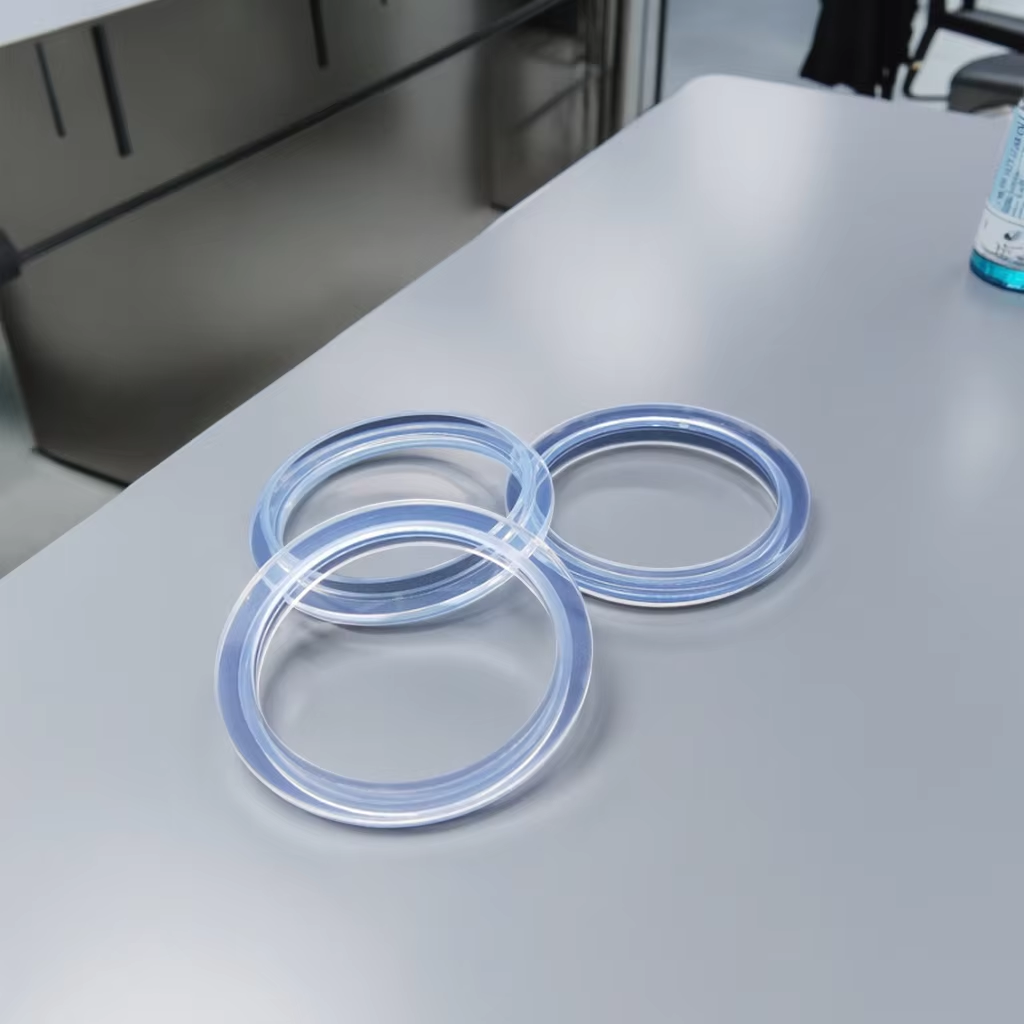

Medical Liquid Clear Silicone Cover Products for Hospital and Laboratory

Medical Liquid Clear Silicone Cover Products for Hospital and Laboratory

Detail Information

1.Custom Medical Liquid Clear Silicone Cover

Medical Liquid Clear Silicone Cover Functional Versatility

High optical clarity (light transmission ≥92% per ASTM D1003) enables real-time patient monitoring (e.g., CPAP mask seals).

Chemically inert (USP Class VI validated), ensuring zero drug adsorption and functionality across -50°C to 250°C, ideal for syringe check valves/aseptic container sealing.

Tear-resistant (ASTM D624 Die C: ≥45 kN/m) with cushioning performance (compression set <10% @150°C), providing IP68-rated waterproofing and dielectric insulation (18 kV/mm per IEC 60243-1) for sensitive instruments.

Medical Liquid Clear Silicone Products Clinical Applications & Functional Advantages

Respiratory Therapy Devices

Key Benefits:

Dynamic sealing maintains >95% air-tightness at 4-20 cmH₂O pressure (ISO 17510)

Transparency (≥92% light transmission, ASTM D1003) enables cyanosis detection

Skin compatibility (pH 5.5-7.0) reduces facial pressure ulcers

Pharmaceutical Containment Systems

Key Benefits:

Zero leachables (USP <381> compliant) prevents drug degradation

-50°C to 250°C stability maintains elasticity during lyophilization/autoclaving

Self-sealing property withstands ≥100 needle penetrations (ISO 8871-3)

Invasive & Implantable Devices

Key Benefits:

Biofilm resistance (Log 6 reduction per ISO 22196)

Hemocompatibility (ISO 10993-4: non-thrombogenic)

Radiolucency (absence of barium sulfate) for imaging clarity

Wearable Diagnostics

Key Benefits:

Adiabatic properties (thermal conductivity 0.2 W/m·K) prevent skin burns

Moisture vapor transmission (≥500 g/m²/day) mitigates maceration

Dielectric strength (18 kV/mm) ensures signal integrity

★Reach out anytime—we’re here to help with expert customization support!

LSR Medical Liquid Silicone Products Components

Mask/Cover

: Transparent CPAP seals enabling real-time patient monitoring

Stopper/Case: Drug adsorption-resistant (-50°C~250°C), USP Class VI compliant for syringe valves

Sleeve: Tear-resistant (ASTM D624) sheathing for endoscopes/sensors with IP68-rated protection

Certifications: FDA 21 CFR 177.2600 & ISO 10993-5/10 biocompatibility

Sterilization: >100 autoclave cycles (121°C, 15psi) or gamma irradiation compatible

Precision: 0.01mm ultra-thin molding for micro-medical devices

Key Technical Specifications of Clear Medical Liquid Silicone Products

Material Performance

Surface antimicrobial efficacy: >99.9% reduction (ISO 22196:2011)

Dielectric strength: 18 kV/mm (IEC 60243-1)

Clinical Validation

Zero extractables/leachables (ISO 10993-17)

Compression set: <10% (ASTM D395) after 500h @150°C

| Feature | Standard | Requirement |

| Biocompatibility | ISO 10993-5/10 | Cytotoxicity/Skin Irritation Class 0 |

| Transparency | ASTM D1003 | Haze ≤1.0% |

Drug Inertness | USP <87> & <88> | Non-pyrogenic, non-hemolytic |

| Tear Strength | ASTM D624 | Die C Tear ≥45 kN/m |

Review

- Loading...

Related Products

Start Your Project Today!

-We are not just a manufacturer of silicone/plastic products, we focus on your business and help you achieve your long-term goals.

- Tel

- *Title

- *Content