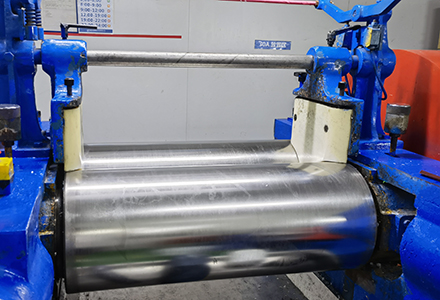

Roller rubber mixing machine

4 units

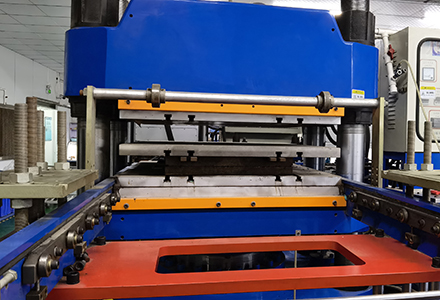

4 units

2 units

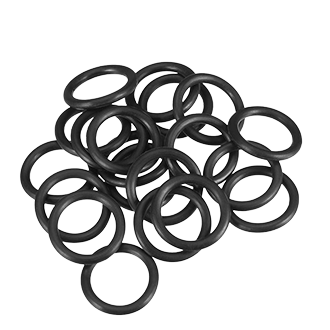

32 units

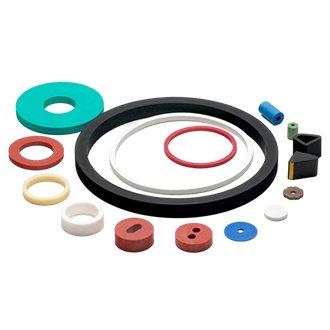

Silicone Cover

Silicone Gasket

Silicone O-ring

Receive detailed Design for Manufacturability reports within 24 hours—your blueprint to seamless production.

Experience rapid prototyping with sample molds crafted within 3-5 days—accelerating your product development journey.

From concept to reality: Our streamlined process delivers production molds in 7-25 days, ensuring efficiency without compromise.