Plastic injection

- Protecting Your Core: How Precision ABS Housings Enhance Buzzer and Vibration Alarm PerformanceDec 3,2025Discover how precision-engineered ABS housings are the critical component for superior buzzer and vibration alarm performance. Our guide explores the material science and design features that enhance sound clarity, maximize vibration transmission, and ensure long-term reliability in demanding industrial, automotive, and consumer applications. Learn why the right housing protects your core technology.

- Why Choose DIN Rail Mount Plastic Enclosures? Streamlining Your Industrial Control Panel BuildDec 1,2025Discover why DIN rail mount plastic enclosures are revolutionizing industrial control panel design. 40-60% faster installation, 35% space optimization, and complete IEC 60715 compliance. Learn how standardized mounting reduces labor costs by 40-60%, minimizes errors by 70-85%, and accelerates time-to-market. cost-benefit comparisons, and workflow optimizations that transform panel building from custom fabrication to efficient, scalable assembly processes for automation systems worldwide.

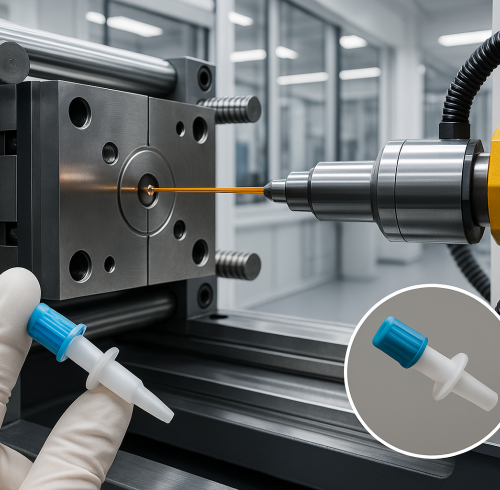

- A Guide to Plastic Enclosure Manufacturing: Injection Molding ProcessNov 18,2025This comprehensive guide delves deep into the injection molding process, exploring each stage from material selection to final production, while providing practical insights for designers, engineers, and product developers seeking to optimize their plastic enclosure designs.

- Is an ABS Enclosure Right for Your Consumer Electronics Product?Nov 17,2025This comprehensive analysis examines whether ABS plastic is the right choice for consumer electronics enclosures. The guide explores ABS material properties, cost-benefit analysis against alternatives, manufacturing considerations, aesthetic capabilities, and environmental factors. Learn when ABS excels for budget-conscious projects requiring good properties and superior surface finishes.Discover how to balance performance, aesthetics, cost, and sustainability for your product's success.

- Case Study: Designing a Weatherproof ABS Housing for Outdoor Sensor & CameraNov 14,2025This case study details designing a weatherproof ABS housing for outdoor sensors and cameras. The project overcame environmental challenges using UV-stabilized ABS and innovative multi-layer sealing to achieve IP67 rating. The housing withstands -30°C to +60°C temperatures, heavy rainfall, and UV exposure while maintaining optimal performance. Optimized injection molding reduced costs by 20%. The solution extends product lifespan to 10+ years in harsh conditions.

- Common ABS Shell Design Mistakes to AvoidNov 13,2025This comprehensive guide reveals the six most critical ABS shell design mistakes that compromise product quality and manufacturability. Learn how to avoid wall thickness inconsistencies, improper rib design, inadequate draft angles, poor boss construction, material shrinkage issues, and environmental stress cracking. Discover practical design solutions and best practices to create durable, cost-effective ABS enclosures that meet quality standards and production requirements.

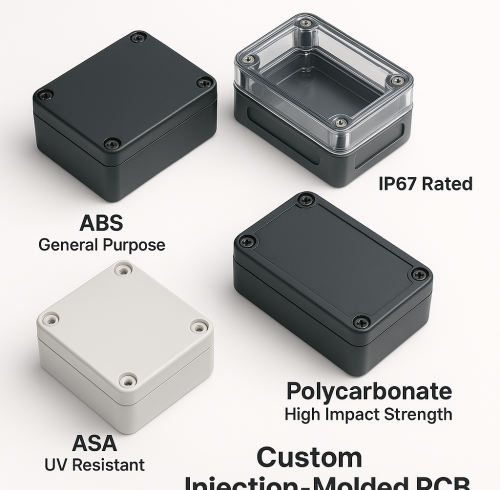

- ABS Enclosures: The Ultimate Guide to Durable, Versatile, and Cost-Effective ProtectionSep 5,2025Discover why Acrylonitrile Butadiene Styrene (ABS) enclosure boxes are the preferred choice for safeguarding sensitive electronics and components across various industries. This comprehensive guide explores ABS's key properties, from superior impact resistance and electrical insulation to chemical resilience and cost-effectiveness. Learn about their diverse applications, delve into material limitations and advanced solutions, and understand important standards like IP and NEMA ratings.

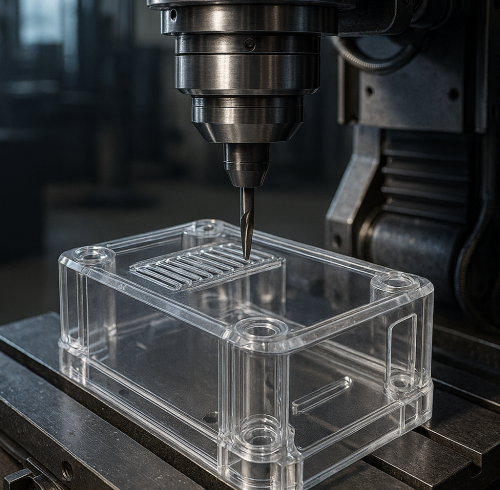

- Advanced CNC Techniques: How to Machine Plastic Enclosures PreciselyAug 18,2025If you're searching for how to make plastic enclosure solutions that demand high precision, durability, and customization, FromRubber advanced CNC machining techniques offer the ultimate pathway.

- Custom Plastic Injection Molding: Process and Benefits with Fromrubber ExpertiseJul 8,2025Custom plastic injection molding is a cornerstone of modern manufacturing, enabling businesses to create precise, high-quality plastic parts tailored to their needs. At Fromrubber, we specialize in delivering innovative customs plastics solutions, combining advanced technology with decades of expertise to meet the demands of industries like automotive, medical, and consumer goods.

- Industrial Plastic Printing for ManufacturingJun 25,2025Elevate your manufacturing projects with From Rubber’s advanced print on plastic solutions. Specializing in custom injection-molded parts, we deliver high-quality, durable prints on plastics for industries like automotive, aerospace, medical, and electronics. Our state-of-the-art printing technologies ensure vibrant, long-lasting graphics on complex plastic components, tailored to your specifications

- Top 10 PCB Enclosure Materials for Optimal PerformanceJun 16,2025When designing or selecting a PCB enclosure, choosing the right material is critical for ensuring durability, functionality, and protection for your electronics. At From Rubber, we specialize in custom injection-molded PCB enclosures, offering tailored solutions to meet diverse industry needs, from consumer electronics to industrial applications