Top 10 PCB Enclosure Materials for Optimal Performance

Top 10 PCB Enclosure Materials for Optimal Performance

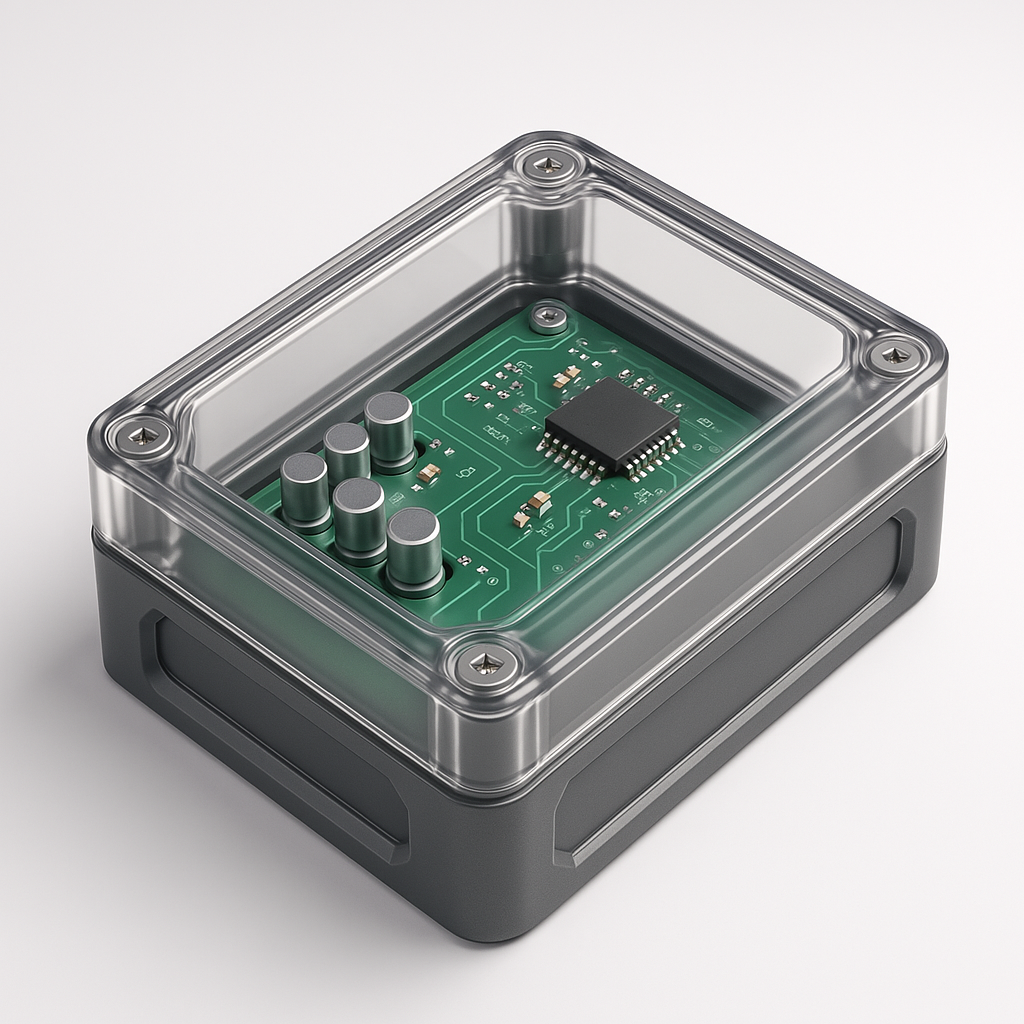

When designing or selecting a PCB enclosure, choosing the right material is critical for ensuring durability, functionality, and protection for your electronics. At From Rubber, we specialize in custom injection-molded PCB enclosures, offering tailored solutions to meet diverse industry needs, from consumer electronics to industrial applications. This guide explores the top 10 materials for PCB enclosures, highlighting their performance characteristics, applications, and key considerations to help you make informed decisions. Backed by our expertise in precision injection molding, we ensure high-quality enclosures that optimize your project’s success.

Why Material Selection Matters for PCB Enclosures

The material of a PCB enclosure impacts its ability to protect printed circuit boards from environmental factors, electromagnetic interference (EMI), and mechanical stress. Factors like thermal management, IP ratings, and cost must align with your project’s requirements. Our team at From Rubber leverages advanced injection molding techniques to craft enclosures in materials like ABS, polycarbonate, and more, ensuring durability and precision for applications in medical, automotive, and IoT industries.

Image Placeholder (Insert Here):

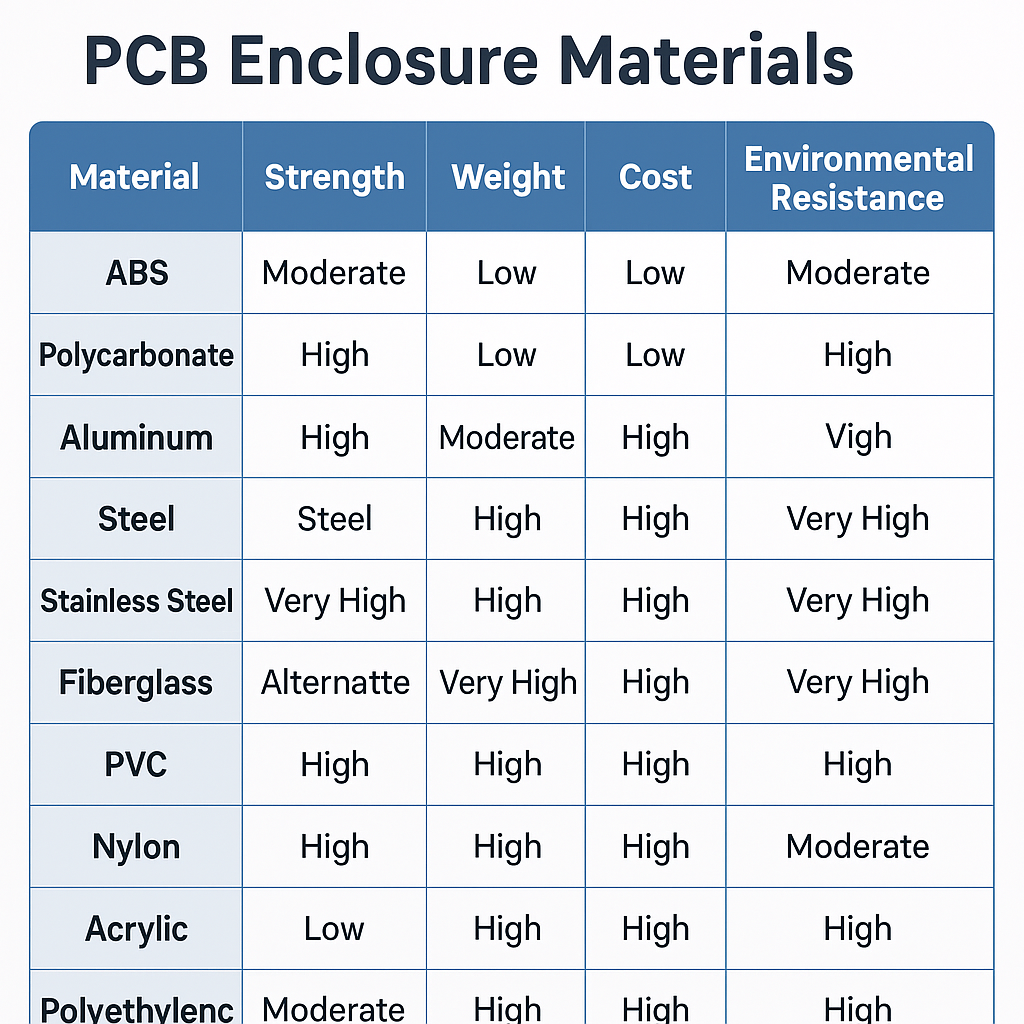

Top 10 PCB Enclosure Materials

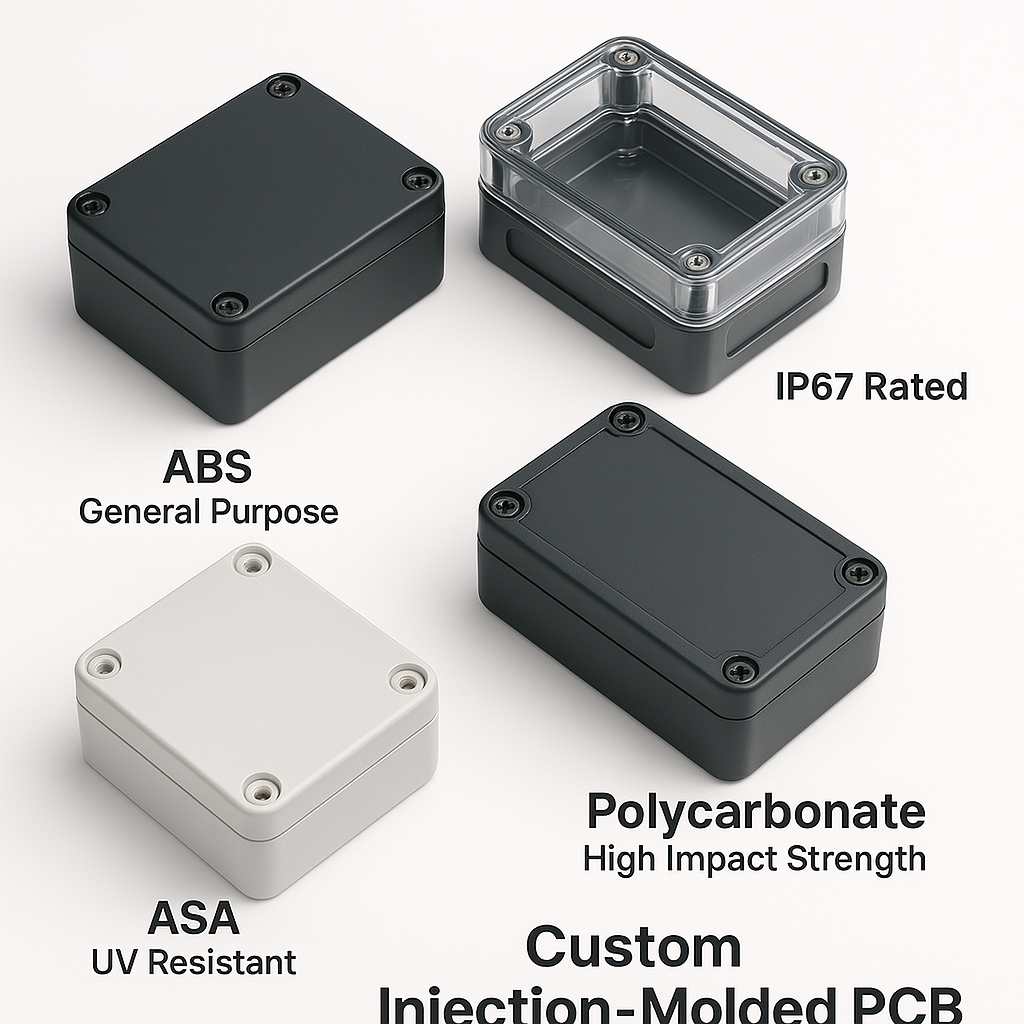

1. ABS (Acrylonitrile Butadiene Styrene)

Properties: Lightweight, impact-resistant, electrically insulating, easy to mold.

Applications: Consumer electronics, home automation devices, budget-friendly projects.

Pros: Cost-effective, customizable with mounting bosses, ideal for indoor use.

Cons: Limited UV stability, lower heat resistance.

Performance: Perfect for lightweight, cost-sensitive applications. From Rubber’s ABS enclosures are precision-molded for seamless PCB integration.

From Rubber Advantage: Our injection molding ensures tight tolerances for ABS enclosures, ideal for high-volume production.

Applications: Consumer electronics, home automation devices, budget-friendly projects.

Pros: Cost-effective, customizable with mounting bosses, ideal for indoor use.

Cons: Limited UV stability, lower heat resistance.

Performance: Perfect for lightweight, cost-sensitive applications. From Rubber’s ABS enclosures are precision-molded for seamless PCB integration.

From Rubber Advantage: Our injection molding ensures tight tolerances for ABS enclosures, ideal for high-volume production.

2. Polycarbonate (PC)

Properties: High impact resistance, UV stability, transparency, thermal resilience.

Applications: Outdoor enclosures, industrial control panels, medical devices.

Pros: Durable, visually appealing, suitable for harsh environments.

Cons: Susceptible to damage from strong chemicals (e.g., alkalis).

Performance: Excellent for rugged applications requiring visibility. From Rubber offers custom polycarbonate enclosures with IP65+ ratings.

From Rubber Advantage: We provide tailored polycarbonate enclosures with custom cutouts and branding options.

Applications: Outdoor enclosures, industrial control panels, medical devices.

Pros: Durable, visually appealing, suitable for harsh environments.

Cons: Susceptible to damage from strong chemicals (e.g., alkalis).

Performance: Excellent for rugged applications requiring visibility. From Rubber offers custom polycarbonate enclosures with IP65+ ratings.

From Rubber Advantage: We provide tailored polycarbonate enclosures with custom cutouts and branding options.

3. ASA (Acrylonitrile Styrene Acrylate)

Properties: Superior UV resistance, good chemical stability, moderate strength.

Applications: Outdoor kiosks, telecommunications, solar equipment.

Pros: Enhanced weatherability compared to ABS, reliable in sunlight.

Cons: Slightly less impact-resistant than polycarbonate.

Performance: Ideal for outdoor PCB enclosures exposed to UV and weather.

From Rubber Advantage: Our ASA enclosures are molded with precision for consistent performance in harsh conditions.

Applications: Outdoor kiosks, telecommunications, solar equipment.

Pros: Enhanced weatherability compared to ABS, reliable in sunlight.

Cons: Slightly less impact-resistant than polycarbonate.

Performance: Ideal for outdoor PCB enclosures exposed to UV and weather.

From Rubber Advantage: Our ASA enclosures are molded with precision for consistent performance in harsh conditions.

4. ASA+PC Blend

Properties: Combines ASA’s weatherability with polycarbonate’s toughness.

Applications: Industrial electronics, outdoor IoT devices, rugged control boxes.

Pros: High durability, excellent for extreme environments (e.g., IK08, IP66/67).

Cons: Higher cost than single-material plastics.

Performance: Optimal for demanding applications requiring both strength and environmental resistance.

From Rubber Advantage: We specialize in blending ASA+PC for custom enclosures with enhanced durability.

Applications: Industrial electronics, outdoor IoT devices, rugged control boxes.

Pros: High durability, excellent for extreme environments (e.g., IK08, IP66/67).

Cons: Higher cost than single-material plastics.

Performance: Optimal for demanding applications requiring both strength and environmental resistance.

From Rubber Advantage: We specialize in blending ASA+PC for custom enclosures with enhanced durability.

5. PC+ABS Blend

Properties: Balances polycarbonate’s strength with ABS’s flexibility and ease of processing.

Applications: Automotive electronics, consumer devices, industrial controls.

Pros: Cost-effective, lightweight, good thermal resistance.

Cons: Moderately expensive compared to pure ABS.

Performance: Versatile for applications needing strength and affordability.

From Rubber Advantage: Our PC+ABS enclosures are designed for precision and scalability.

Applications: Automotive electronics, consumer devices, industrial controls.

Pros: Cost-effective, lightweight, good thermal resistance.

Cons: Moderately expensive compared to pure ABS.

Performance: Versatile for applications needing strength and affordability.

From Rubber Advantage: Our PC+ABS enclosures are designed for precision and scalability.

6. Aluminum

Properties: Lightweight, excellent thermal conductivity, inherent EMI shielding.

Applications: Automotive, high-heat electronics, telecommunications.

Pros: Cost-effective for metal, easy to machine, corrosion-resistant.

Cons: Lacks built-in mounting features, heavier than plastics.

Performance: Ideal for heat dissipation and EMI-sensitive applications.

From Rubber Advantage: We partner with metal fabricators to offer hybrid solutions integrating aluminum with custom plastic components.

Applications: Automotive, high-heat electronics, telecommunications.

Pros: Cost-effective for metal, easy to machine, corrosion-resistant.

Cons: Lacks built-in mounting features, heavier than plastics.

Performance: Ideal for heat dissipation and EMI-sensitive applications.

From Rubber Advantage: We partner with metal fabricators to offer hybrid solutions integrating aluminum with custom plastic components.

7. Stainless Steel

Properties: High corrosion resistance, durable, hygienic.

Applications: Marine environments, food processing, medical equipment.

Pros: Resistant to scratching, staining, and corrosion; sanitary.

Cons: Heavier, more expensive, harder to modify.

Performance: Best for hygienic or corrosion-prone environments.

From Rubber Advantage: We provide custom plastic enclosures compatible with stainless steel components for hybrid designs.

Applications: Marine environments, food processing, medical equipment.

Pros: Resistant to scratching, staining, and corrosion; sanitary.

Cons: Heavier, more expensive, harder to modify.

Performance: Best for hygienic or corrosion-prone environments.

From Rubber Advantage: We provide custom plastic enclosures compatible with stainless steel components for hybrid designs.

8. Polyamide

Properties: Tough, wear-resistant, good for moving parts.

Applications: Power tools, enclosures with sliding components.

Pros: Durable in high-wear applications, good friction resistance.

Cons: Absorbs moisture, sensitive to acids.

Performance: Suited for mechanical durability but not humid environments.

From Rubber Advantage: Our polyamide enclosures are molded for precision in high-wear applications.

Applications: Power tools, enclosures with sliding components.

Pros: Durable in high-wear applications, good friction resistance.

Cons: Absorbs moisture, sensitive to acids.

Performance: Suited for mechanical durability but not humid environments.

From Rubber Advantage: Our polyamide enclosures are molded for precision in high-wear applications.

9. Polyethylene

Properties: High chemical and moisture resistance, lightweight.

Applications: Chemical plants, industrial environments with corrosive exposure.

Pros: Cost-effective, durable in harsh chemical settings.

Cons: Lower mechanical strength than polycarbonate or metals.

Performance: Ideal for chemically aggressive environments.

From Rubber Advantage: We offer polyethylene enclosures for specialized industrial applications.

Applications: Chemical plants, industrial environments with corrosive exposure.

Pros: Cost-effective, durable in harsh chemical settings.

Cons: Lower mechanical strength than polycarbonate or metals.

Performance: Ideal for chemically aggressive environments.

From Rubber Advantage: We offer polyethylene enclosures for specialized industrial applications.

10. Fiberglass Reinforced Plastic (FRP)

Properties: Strong, lightweight, corrosion-resistant.

Applications: Industrial control systems, outdoor enclosures in harsh environments.

Pros: Combines plastic versatility with fiberglass strength.

Cons: Can splinter during modification, producing fine dust.

Performance: Excellent for high-performance, rugged applications.

From Rubber Advantage: Our FRP enclosures are custom-molded for durability and environmental resistance.

Applications: Industrial control systems, outdoor enclosures in harsh environments.

Pros: Combines plastic versatility with fiberglass strength.

Cons: Can splinter during modification, producing fine dust.

Performance: Excellent for high-performance, rugged applications.

From Rubber Advantage: Our FRP enclosures are custom-molded for durability and environmental resistance.

How to Choose the Right Material for Your PCB Enclosure

Selecting the optimal PCB enclosure material depends on your project’s specific needs. Consider these factors:

Key Consideration Factors

- Environmental Conditions: Choose UV-resistant materials (ASA, polycarbonate) for outdoor use or corrosion-resistant options (stainless steel) for marine applications.

- Thermal Management: Opt for aluminum for high-heat dissipation or ensure proper ventilation in plastic enclosures.

- EMI Shielding: Use metals or coated plastics for electronics sensitive to electromagnetic interference.

- Cost vs. Performance: Balance budget with durability needs—ABS for cost savings, ASA+PC for premium performance.

- Regulatory Compliance: Ensure materials meet standards like UL94 (flammability) or NEMA/IP ratings (environmental protection).

At From Rubber, our expertise in custom injection molding ensures your PCB enclosure meets these requirements with precision. Our ISO 9001:2015-certified processes and advanced facilities in China guarantee high-quality, cost-effective solutions tailored to your specifications.

Why Choose From Rubber for Your PCB Enclosures?

- Custom Solutions: Specialized in injection-molded enclosures tailored to your PCB’s dimensions, mounting needs, and environmental requirements.

- Material Expertise: From ABS to FRP, offering a wide range of materials to match performance goals.

- Global Reach: Serving industries worldwide (medical, automotive, IoT) with fast delivery and competitive pricing.

- Quality Assurance: ISO 9001:2015 certification ensures consistent quality and reliability.

- Sustainability: Incorporates eco-friendly materials and processes for sustainable manufacturing.

Conclusion

Choosing the right material for your PCB enclosure is essential for protecting your electronics and ensuring long-term performance. Whether you need cost-effective ABS, UV-resistant polycarbonate, or robust aluminum, From Rubber delivers custom injection-molded enclosures that meet your unique needs. Explore our range of high-quality PCB enclosures or contact us for a free consultation to design the perfect solution for your project.

Call to Action

Visit

From Rubber

to explore our custom PCB enclosure solutions or request a quote today!About From Rubber

With over a decade of experience, From Rubber is a leading manufacturer of custom injection-molded parts, specializing in PCB enclosures for industries like medical, automotive, and IoT. Based in China, our ISO 9001:2015-certified facility delivers precision, quality, and cost-effective solutions worldwide. Learn more at .

Trust Signals

- Author: Dr. Jane Lee, Materials Engineer with 15 years of experience in injection molding and electronics packaging.

- Reviewed: September 2025, ensuring up-to-date industry standards.

- Certifications: ISO 9001:2015, RoHS-compliant materials.