Why is the resistance of a conductive pill in the silicone keypad unstable or too high?

Understanding Conductive Pill Resistance Instability in Silicone Keypads

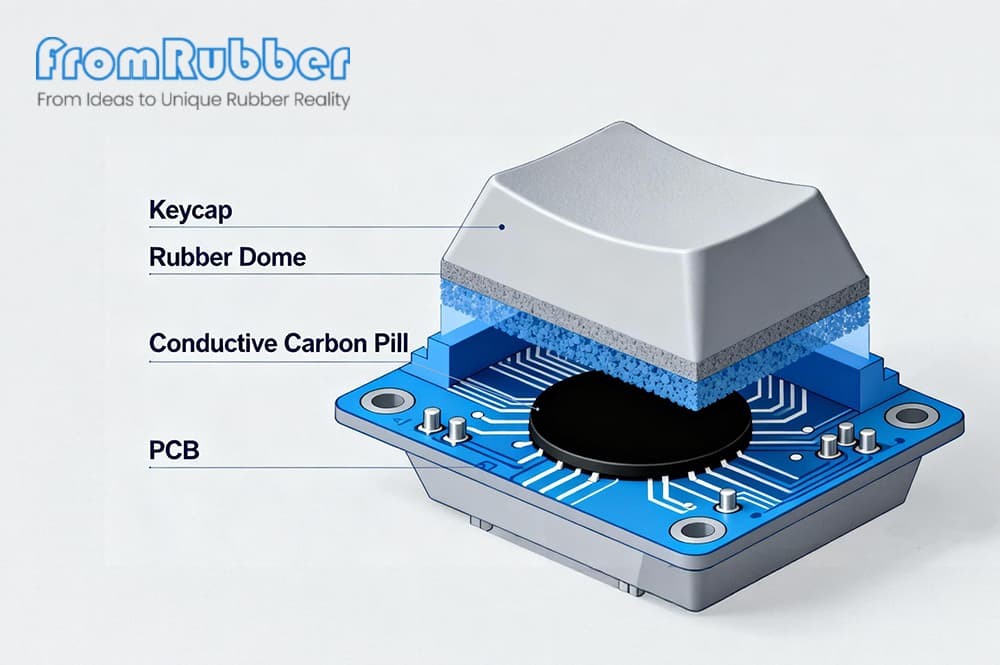

Silicone keypads with conductive pills are widely used in consumer electronics, medical devices, industrial controls, and automotive applications due to their durability, tactile feedback, and reliability. However, a common technical challenge faced by manufacturers and engineers is the instability or excessively high resistance of conductive pills, which can lead to inconsistent keypad performance, missed keystrokes, or complete device failure. This comprehensive analysis explores the root causes of these resistance issues and provides practical solutions for optimizing conductive pill performance.

Key Insight: The resistance instability in conductive pills is rarely caused by a single factor but is typically the result of multiple interacting variables including material composition, manufacturing processes, environmental conditions, and design considerations.

Primary Causes of Resistance Instability and High Resistance

Conductive pills in silicone keypads function by creating an electrical connection between two circuit traces when the key is pressed. The resistance of this connection must fall within a specified range (typically 100Ω to 1kΩ) for reliable operation. When resistance becomes unstable or exceeds acceptable limits, the following factors are most commonly responsible:

| Root Cause Category | Specific Issue | Impact on Resistance |

|---|---|---|

| Material Composition | Inconsistent carbon/silver particle distribution | Creates irregular conductive pathways leading to resistance fluctuations |

| Manufacturing Process | Improper curing time or temperature | Results in incomplete polymer cross-linking and unstable conductivity |

| Environmental Factors | Humidity absorption by silicone matrix | Changes dielectric properties and increases surface resistance |

| Design Limitations | Insufficient pill contact area | Reduces effective conduction paths and increases resistance |

| Age and Wear | Carbon particle migration over time | Gradually alters conductive network integrity |

Material Composition Factors

The conductive pills in silicone keypads are typically composed of silicone rubber impregnated with conductive particles, most commonly carbon or silver-coated particles. The uniformity of particle distribution within the silicone matrix directly determines the consistency of electrical resistance. When particle dispersion is uneven, conductive pathways become irregular, leading to resistance values that fluctuate with each key press. Higher concentrations of conductive filler generally lower resistance but can compromise the mechanical properties of the silicone, creating a delicate balance that manufacturers must achieve.

Particle Distribution Issues

During the mixing process, conductive particles can agglomerate or settle unevenly, creating localized areas of high and low conductivity within the same pill. This inconsistency becomes particularly problematic when the pill makes contact with the circuit board, as different areas of the pill surface may exhibit significantly different resistance values.

Filler Material Quality

Lower quality carbon black or silver particles may contain impurities or irregular shapes that prevent consistent electrical contact between particles. Premium conductive fillers with controlled particle size distribution and surface treatments provide more reliable performance but at increased cost.

Silicone Matrix Compatibility

The silicone formulation must be compatible with the conductive filler to prevent phase separation or filler migration. Specialized coupling agents are often required to ensure strong bonding between the hydrophobic silicone and hydrophilic conductive particles.

Manufacturing Process Variables

The manufacturing process plays a critical role in determining the final resistance characteristics of conductive pills. Inconsistent process parameters can introduce significant variability even when using identical raw materials. The table below outlines key manufacturing factors and their effects on resistance stability:

| Manufacturing Process Variables Affecting Conductive Pill Resistance | ||

|---|---|---|

| Process Stage | Optimal Conditions | Consequences of Deviation |

| Mixing | Controlled vacuum mixing for 15-20 minutes at specific shear rates | Incomplete dispersion leads to resistance variations up to 300% |

| Molding | Precise temperature control (±2°C) and injection pressure | Temperature variations cause inconsistent cross-linking and resistance drift |

| Curing | Two-stage curing: 120°C for 15 minutes, then 180°C for 30 minutes | Incomplete curing results in unstable resistance that changes with temperature |

| Post-Curing | Controlled cooling at 2°C/minute to room temperature | Rapid cooling introduces internal stresses that affect conductive pathways |

| Quality Control | 100% resistance testing with statistical process control | Without testing, defective pills may pass to assembly, causing field failures |

Environmental and Operational Factors

Silicone keypads are often deployed in challenging environments that can significantly impact the resistance stability of conductive pills. Understanding these external factors is essential for designing keypads that maintain consistent performance throughout their operational life.

Humidity and Moisture: Silicone rubber is naturally hygroscopic and can absorb moisture from the environment. When water molecules penetrate the silicone matrix, they can create alternative conductive paths or interfere with existing ones, causing resistance to fluctuate with ambient humidity. In extreme cases, absorbed moisture can lead to electrochemical migration between conductive particles, permanently altering the resistance characteristics.

Temperature Variations: Both silicone rubber and conductive fillers exhibit temperature-dependent electrical properties. The resistance of carbon-filled silicone typically decreases with increasing temperature (negative temperature coefficient), but the relationship is not always linear or predictable. Repeated thermal cycling can cause differential expansion between the silicone matrix and conductive particles, potentially disrupting the conductive network over time.

Mechanical Stress and Compression Set: Each keypress applies mechanical stress to the conductive pill, compressing the silicone matrix and forcing conductive particles into closer contact. Over millions of actuations, the silicone may develop compression set (permanent deformation), changing the contact force and therefore the resistance. Additionally, repeated compression can cause conductive particles to migrate within the matrix, gradually altering the conductive pathways.

Design-Related Resistance Issues

The physical design of the conductive pill and surrounding keypad structure significantly influences resistance stability. Common design pitfalls include:

Insufficient Contact Area

Pills with small contact surfaces concentrate current density, leading to localized heating and accelerated degradation. The minimum recommended contact area is 2.5mm² for typical applications, with larger areas preferred for high-reliability requirements.

Poor Pill Alignment

If the conductive pill does not align precisely with the circuit pad, only partial contact occurs, increasing resistance. Tolerances should ensure at least 80% overlap between pill and pad in all expected manufacturing variations.

Inadequate Actuation Force

Too little force results in insufficient compression of the conductive pill, creating high-resistance contact. The ideal actuation force balances user comfort with reliable electrical contact, typically between 1.5N and 2.5N.

Solutions for Stable and Low Resistance

Addressing conductive pill resistance issues requires a systematic approach across material selection, manufacturing, design, and testing. The following strategies have proven effective in producing silicone keypads with stable, low-resistance conductive pills:

| Solution Area | Implementation Method | Expected Improvement |

|---|---|---|

| Material Optimization | Use of dual-filler systems (carbon + silver-coated copper) | Reduces resistance by 40-60% while maintaining cost effectiveness |

| Process Control | Implementation of Six Sigma methodologies in mixing and curing | Reduces resistance variability from ±50% to ±10% |

| Surface Treatment | Plasma treatment of pill surface before assembly | Improves initial contact resistance by creating cleaner surface |

| Environmental Protection | Application of conformal coating on PCB around contact area | Prevents contamination migration and maintains stable resistance |

| Design Enhancement | Increased pill dome height for greater compression travel | Ensures consistent contact pressure across tolerance range |

Industry Best Practice: Integrated Resistance Management

The most successful keypad manufacturers implement a holistic approach that begins with material selection and continues through design, manufacturing, and quality assurance. By treating resistance stability as a system property rather than a component characteristic, they achieve consistent performance even in demanding applications with lifetimes exceeding 10 million actuations.

Testing and Quality Assurance Protocols

Comprehensive testing is essential to ensure conductive pill resistance remains within specifications throughout the product lifecycle. Recommended testing protocols include:

Initial Resistance Testing: Every conductive pill should be tested for resistance immediately after manufacturing. Automated testing systems can measure resistance at multiple points on each pill to ensure uniformity. Acceptance criteria should include both absolute resistance values (typically 100Ω-500Ω) and consistency across pills (variation less than 20%).

Environmental Stress Testing: Samples from each production batch should undergo accelerated aging tests including thermal cycling (-40°C to +85°C for 100 cycles), humidity exposure (85% RH at 85°C for 168 hours), and UV resistance testing. Resistance measurements before and after these tests reveal potential instability issues before products reach customers.

Lifecycle Testing: Actuation testing to at least 1 million cycles with periodic resistance measurements identifies wear patterns and predicts long-term performance. The resistance should remain within 30% of initial values throughout the tested lifecycle.

Future Trends in Conductive Pill Technology

As electronic devices continue to evolve, conductive pill technology is advancing to meet new challenges. Emerging trends include:

Nanocomposite Materials: Incorporating carbon nanotubes or graphene into the silicone matrix creates more robust conductive networks with lower filler concentrations, resulting in more stable resistance and better mechanical properties.

Smart Manufacturing: Industry 4.0 technologies including real-time process monitoring with IoT sensors and AI-driven quality control systems allow for immediate adjustment of manufacturing parameters when resistance deviations are detected.

Alternative Conductive Materials: Research into intrinsically conductive polymers and metal-mesh structures embedded in silicone may eventually replace traditional carbon-filled systems, offering potentially more stable resistance characteristics.

Conclusion

Resistance instability and high resistance in silicone keypad conductive pills result from a complex interplay of material, manufacturing, environmental, and design factors. By understanding these underlying causes and implementing comprehensive solutions across the product development cycle, manufacturers can produce reliable keypads with consistent electrical performance. The most effective approach combines high-quality materials with precise process control, robust design principles, and rigorous testing protocols. As technology advances, new materials and manufacturing techniques promise even greater stability and reliability for conductive pill-based switching systems.

Final Recommendation: For optimal results, partner with a silicone keypad manufacturer that demonstrates thorough understanding of conductive pill resistance factors, maintains tight process controls, and provides comprehensive testing data. Request batch testing reports and lifecycle data before finalizing your keypad specification to ensure the conductive pills will maintain stable resistance throughout your product's intended lifespan.