Tactile Feedback in Silicone Keypads: Science and Engineering

Introduction

At FromRubber, we pride ourselves on being at the forefront of silicone keypad manufacturing, with years of experience in delivering high-quality, custom-designed keypads to a diverse range of industries. One of the most crucial aspects of a great silicone keypad is its tactile feedback. Tactile feedback not only enhances the user experience but also plays a significant role in the functionality and usability of devices. In this article, we will explore the science and engineering behind tactile feedback in silicone keypads.

The Science of Tactile Feedback

How Our Brain Perceives Tactile Sensations

Our sense of touch is incredibly complex. When we press a silicone keypad, nerve endings in our fingertips detect mechanical forces. These forces are then converted into electrical signals that are sent to our brain. The brain interprets these signals, allowing us to perceive the feel of the keypad, such as its hardness, shape, and the amount of resistance when pressed.

Material Properties and Tactile Sensation

Silicone, as a material, has unique properties that contribute to tactile feedback. The elasticity of silicone allows it to deform under pressure and then quickly return to its original shape. This snap-back action is what creates the distinct "click" or tactile response that users feel. At FromRubber, we carefully select different grades of silicone, considering factors like hardness (measured in Shore durometer).

For example, a softer silicone (lower Shore durometer) might provide a more cushioned feel, while a harder silicone (higher Shore durometer) can offer a more distinct and firm tactile response.

Engineering Principles for Tactile Feedback

Actuation Force

Actuation force is the amount of pressure required to activate a keypad switch. It is a critical engineering parameter. A well-designed silicone keypad should have an actuation force that is neither too high, which would make it difficult to press, nor too low, which could result in accidental presses.

According to industry standards, for consumer electronics, an actuation force of around 130 grams is often recommended. At FromRubber, our engineers use state-of-the-art equipment to precisely measure and adjust the actuation force during the manufacturing process. We conduct extensive testing to ensure that the actuation force of our silicone keypads meets the specific requirements of our clients, whether it's for a medical device, industrial control panel, or consumer product.

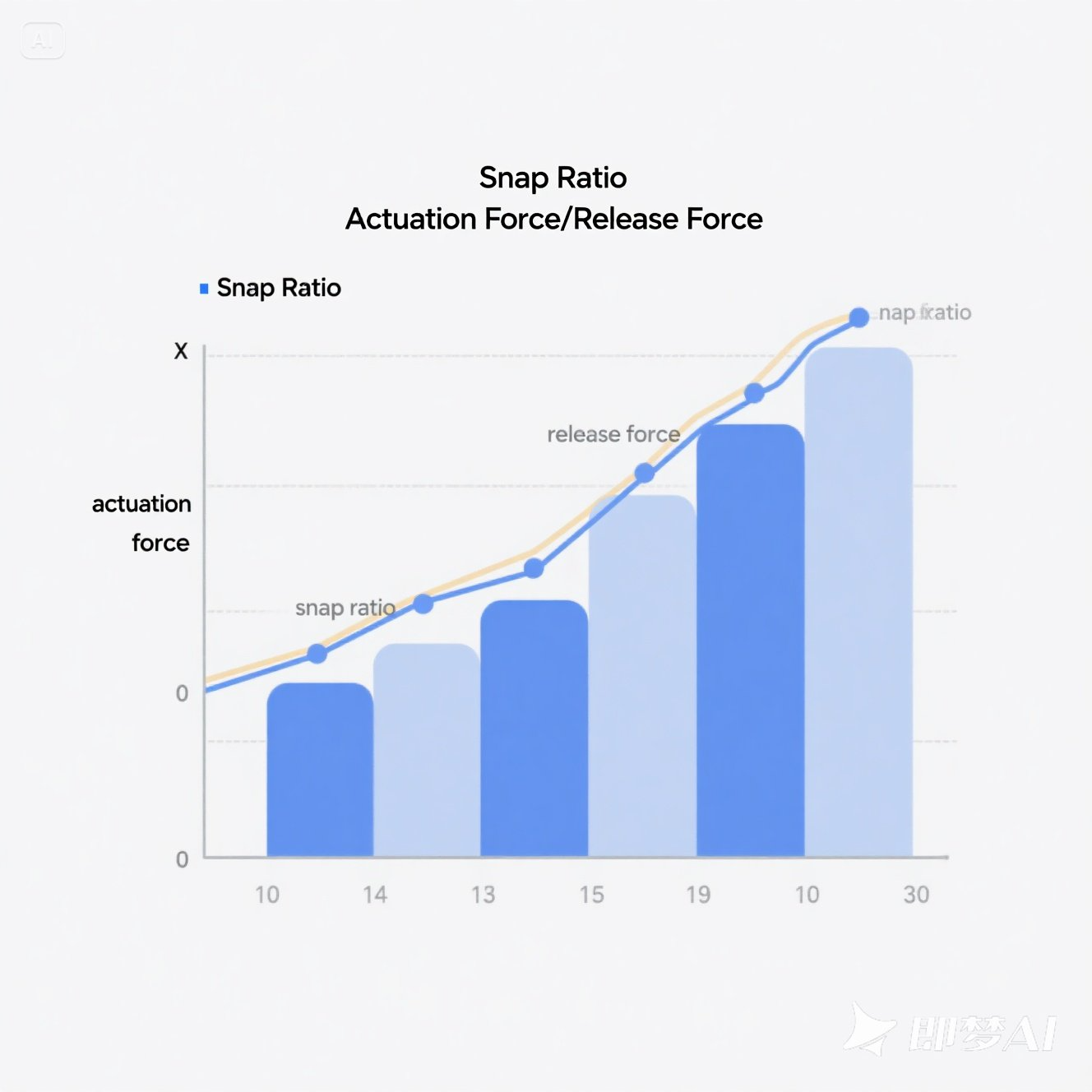

Snap Ratio

The snap ratio is another important concept in keypad engineering. It is defined as the ratio of the actuation force to the release force. A snap ratio of around 50% is generally considered ideal. This means that the force required to press the keypad is approximately the same as the force required for it to snap back.

A proper snap ratio ensures a balanced tactile experience, where the user feels a satisfying "click" when pressing and releasing the keypad. Our team at FromRubber has in-depth knowledge of snap ratio optimization. We use advanced simulation software during the design phase to predict and fine-tune the snap ratio of our silicone keypads. By carefully controlling factors such as the geometry of the keypad buttons and the thickness of the silicone material, we can achieve the desired snap ratio for optimal tactile feedback.

Button Design and Geometry

The design and geometry of the keypad buttons also have a profound impact on tactile feedback. The shape of the button, its size, and the presence of features like domes or ridges can all influence how the user perceives the keypad. For example, buttons with a slightly concave shape can provide a more natural fit for the fingertip, enhancing the tactile experience.

At FromRubber, we offer a wide range of button design options. Our experienced designers work closely with clients to create custom button geometries that not only look aesthetically pleasing but also provide excellent tactile feedback. We also use techniques like laser-etching to create textured surfaces on the buttons, which can further improve grip and tactile response.

Real-World Applications and Case Studies

Consumer Electronics

In the world of consumer electronics, tactile feedback in silicone keypads is crucial for user satisfaction. For example, in remote controls, a well-designed keypad with good tactile feedback allows users to easily navigate through menus without having to look at the buttons constantly. FromRubber has supplied silicone keypads to leading consumer electronics manufacturers.

Our keypads are known for their consistent tactile response, which has helped our clients improve the user experience of their products. One of our clients, a major player in the smart home device market, reported a significant decrease in customer complaints related to button functionality after switching to our silicone keypads.

Medical Devices

In medical devices, tactile feedback is not only about user experience but also about safety and accuracy. Healthcare professionals need to be able to operate devices with precision. Our silicone keypads, designed with strict quality control and attention to tactile feedback, are used in various medical equipment, such as diagnostic devices and surgical instruments.

For instance, in a blood glucose monitor, the keypad's tactile response allows patients to accurately enter data and operate the device. Our keypads are made from medical-grade silicone, which meets the highest standards of biocompatibility and hygiene.

Industrial Machinery

Industrial machinery often operates in harsh environments, and the keypad needs to be robust and provide reliable tactile feedback. FromRubber's silicone keypads are designed to withstand extreme temperatures, humidity, and mechanical stress. In industrial control panels, our keypads enable operators to make quick and accurate inputs, even in noisy and chaotic industrial settings.

A case in point is a large-scale manufacturing plant that upgraded its control panel keypads to our products. They reported improved operational efficiency as operators could interact with the machinery more confidently due to the enhanced tactile feedback of our silicone keypads.

FromRubber's Expertise in Tactile-Optimized Silicone Keypads

With years of experience in the silicone keypad industry, FromRubber has developed a deep understanding of the science and engineering behind tactile feedback. Our team consists of highly qualified engineers and designers who are experts in material science, mechanical engineering, and product design. We are committed to using the latest technologies and manufacturing processes to create silicone keypads with exceptional tactile feedback.

We also have a state-of-the-art manufacturing facility equipped with advanced machinery for precision molding, laser-etching, and quality testing. Our quality control process is rigorous, ensuring that every silicone keypad we produce meets the highest standards of tactile performance, durability, and reliability. When you choose FromRubber for your silicone keypad needs, you are partnering with a company that has the expertise, experience, and commitment to deliver products that exceed your expectations.

Conclusion

Tactile feedback in silicone keypads is a fascinating blend of science and engineering. By understanding the principles behind it and leveraging advanced manufacturing techniques, FromRubber is able to produce silicone keypads that offer an outstanding user experience.

Whether you are in the consumer electronics, medical, or industrial sector, our custom-designed silicone keypads can meet your specific requirements for tactile feedback, functionality, and durability.