Top Quality Rubber Parts Manufacturer for Custom OEM Solutions

1. What Are Rubber Parts and Their Applications

Rubber parts are components crafted from natural or synthetic rubber, valued for their flexibility, resilience, and durability across various applications. They excel in sealing, vibration dampening, noise reduction, insulation, and protection against environmental factors.

1.1 Common Types of Rubber Parts

- Custom Gaskets: Ensure tight seals between metal, glass, or plastic surfaces to prevent leaks of air, fluids, or gases.

- Seals: Used in mechanical systems to block contamination and maintain pressure.

- O-rings: Reliable sealing rings for both static and dynamic applications.

- Molded Parts: Custom-shaped components tailored for specific performance needs.

- Extrusions: Continuous rubber profiles for weatherstripping, tubing, and edge protection.

1.2 Industries That Rely on Rubber Components

Rubber parts are integral to numerous industries:

- Automotive: Engine gaskets, weatherstripping, suspension bushings, seals.

- Medical Devices: Silicone seals, tubing, and hygienic components.

- Electronics: Keypads, protective covers, vibration isolators.

- Industrial Machinery: Shock absorbers, conveyor belts, protective boots.

- Consumer Goods: Appliance seals, fitness equipment grips, protective pads.

1.3 Why Material Selection Matters

Selecting the right rubber material is critical for performance, safety, and longevity. Key considerations include:

- Durability: Resistance to wear and tear.

- Resistance: Protection against heat, chemicals, and weather.

- Flexibility: Adaptability across temperature ranges.

- Compliance: Adherence to standards like FDA or RoHS.

A well-chosen material ensures reliability under specific conditions, from extreme engine heat to stringent medical hygiene requirements.

2. Understanding Rubber Manufacturing Processes

The manufacturing method chosen by a rubber parts manufacturer significantly impacts quality, cost, and performance. Below are the primary processes and their applications.

2.1 Injection Molding

- How it Works: Liquid or softened rubber is injected into a mold.

- Best for: High-volume production of precise parts like silicone rubber buttons, O-rings, or complex seals.

- Advantages: Consistent quality, tight tolerances, fast cycle times.

- Limitations: Higher tooling costs; less suited for small runs.

2.2 Compression Molding

- How it Works: Rubber is placed in a mold cavity, then pressed and heated until cured.

- Best for: Low to medium quantities, larger or thicker parts, custom gaskets.

- Advantages: Lower tooling costs, versatile for rubbers like EPDM and neoprene.

- Limitations: Slower production, less precise for intricate details.

2.3 Transfer Molding

- How it Works: Rubber is pushed into mold cavities through a runner system before curing.

- Best for: Parts with inserts (e.g., metal-rubber combinations), medium runs.

- Advantages: Suitable for detailed parts, less waste than compression molding.

- Limitations: Higher tooling costs than compression molding.

2.4 Extrusion

- How it Works: Rubber is forced through a die to create continuous profiles.

- Best for: Tubing, seals, weatherstrips, and long-length parts.

- Advantages: Cost-effective for continuous shapes, high-volume capability.

- Limitations: Restricted to constant cross-section designs.

2.5 Calendering

- How it Works: Rubber is rolled into thin sheets or coated onto fabrics.

- Best for: Conveyor belts, coated textiles, sheet rubber.

- Advantages: Continuous production, precise thickness control.

- Limitations: Limited to flat sheet applications.

Choosing the Right Process: The optimal method depends on part design, material, production volume, and budget. OEM/ODM factories like FromRubber evaluate these factors to deliver durability, cost efficiency, and timely production.

3. Key Materials Used in Rubber Parts Manufacturing

Material selection is pivotal for performance and durability. Below is a comparison of common rubber materials used in custom rubber parts manufacturing.

3.1 Common Rubber Materials and Their Properties

| Material | Strengths | Common Uses | Limits |

|---|---|---|---|

| Silicone | High heat resistance, flexible, food/medical-safe | Medical devices, kitchenware, electronics seals | Lower tear strength |

| Natural Rubber (NR) | Excellent elasticity, abrasion resistance | Automotive mounts, vibration dampers | Poor resistance to oils, solvents, ozone |

| Nitrile (NBR) | Outstanding oil and fuel resistance | Seals, O-rings, industrial hoses | Hardens in cold temperatures |

| EPDM | Excellent weather, UV, and ozone resistance | Outdoor seals, roofing, weatherstrips | Poor resistance to oils/fuels |

| Neoprene (CR) | Balanced resistance to weather, oil, abrasion | Gaskets, wet suits, industrial seals | Lower flexibility in extreme cold |

3.2 Factors That Drive Material Choice

- Durability: Longevity under repeated stress.

- Resistance: Protection against oil, UV, chemicals, or water.

- Flexibility: Essential for seals, gaskets, or vibration dampening.

- Temperature Tolerance: Critical for high-heat environments like engines or electronics.

3.3 Why Silicone and Rubber Combinations Work

Combining silicone’s heat resistance with materials like nitrile’s oil resistance creates robust parts for demanding automotive and industrial applications. This approach, used by FromRubber, ensures high-performance, cost-effective components.

4. What to Look for When Choosing a Rubber Parts Manufacturer

Selecting the right manufacturer is crucial for project success. Here’s what to prioritize in the U.S. market.

4.1 Certifications and Quality Standards

- ISO 9001: Ensures robust quality management.

- RoHS & REACH: Compliance with environmental guidelines.

- FDA Compliance: Required for food or medical-grade parts.

4.2 Manufacturing Capabilities and Technology

- Rubber Molding Services: Injection, compression, and transfer molding.

- Extrusion and Calendering: For continuous profiles and sheets.

- In-House Tooling: Speeds up production and ensures precision.

4.3 Customization Expertise

Support for design assistance, prototyping, and material selection ensures custom seals, O-rings, or silicone buttons meet exact specifications.

4.4 OEM and ODM Flexibility

Handles low-volume prototypes to high-volume production, working from your designs or creating them for you.

4.5 Proven Track Record

Success in automotive, electronics, medical, or industrial sectors, backed by a strong client portfolio.

4.6 Lead Time and On-Time Delivery

- Reliability: Consistent delivery performance.

- Clear Schedules: Transparent production timelines.

- Rush Orders: Capability to meet urgent demands.

4.7 Pricing and Volume Scalability

- Competitive Pricing: Transparent quotes for small and bulk orders.

- Cost Optimization: Suggestions for high-volume savings.

4.8 After-Sales Support and Warranty

Warranties and technical support for post-delivery issues, with quick resolution of problems.

5. Benefits of Partnering with an OEM/ODM Factory like FromRubber

FromRubber stands out as an OEM/ODM partner, delivering quality, speed, and cost efficiency for U.S. customers.

5.1 Why Choose FromRubber

1. Proven Expertise

- Specializes in silicone and rubber parts for automotive, electronics, medical, and industrial markets.

- Extensive experience in custom gaskets, seals, O-rings, and molded parts.

2. Advanced Technology

- State-of-the-art molding machines for injection, compression, transfer, and extrusion.

- In-house CNC mold making for precision and speed.

- Automated inspection systems for consistent quality.

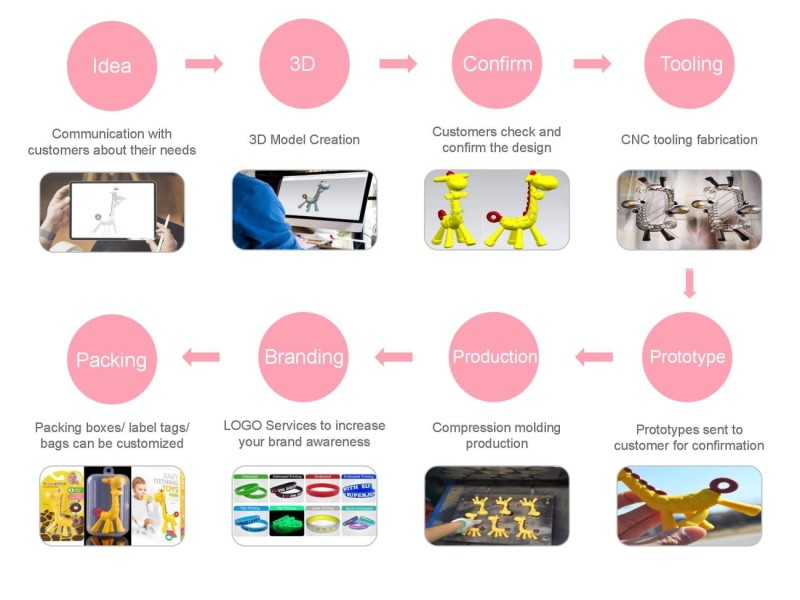

3. Flexible Design and Prototyping

- Rapid prototyping in days.

- Full support from design to production.

- Scalable from low to high volumes.

4. Competitive and Scalable Production

- Cost-effective pricing for all order sizes.

- Flexible MOQs for various business needs.

- Seamless scaling from prototype to mass production.

5. Global Reach

- Reliable worldwide shipping with U.S.-specific logistics.

- Handles export compliance and documentation.

6. Quality Assurance

- ISO, RoHS, REACH, and FDA compliance.

- Rigorous testing for durability and performance.

| Feature | FromRubber Advantage |

|---|---|

| Material Range | Silicone, EPDM, Nitrile, Neoprene, and more |

| Quality Control | 100% inspection, industry certifications |

| Production Speed | Short lead times, rapid prototyping |

| Customization | OEM/ODM design, tooling, tailored specs |

| Shipping | Global delivery with U.S.-friendly logistics |

Example: A U.S. electronics company needed a custom silicone rubber button with tight tolerances. FromRubber delivered prototypes in under a week, reduced production costs by 12% through design tweaks, and scaled to 50,000 units without delays.

6. Common Challenges in Sourcing Rubber Parts and How to Overcome Them

Sourcing rubber parts can present challenges, but FromRubber mitigates these effectively.

6.1 Material Selection Complexity

Challenge: Choosing between silicone, EPDM, nitrile, or others based on durability, heat resistance, and flexibility.

Solution: FromRubber provides clear material comparisons, testing, and samples to align with your needs and budget.

6.2 Manufacturing Lead Times

Challenge: Delays from poor planning or outdated equipment.

Solution: Modern molding and extrusion equipment, organized schedules, and rush-order options ensure timely delivery.

6.3 Quality Control Issues

Challenge: Inconsistent sizing, defects, or poor finishes.

Solution: ISO-certified QC checks at every stage, from raw materials to final inspection, ensure precise, reliable parts.

6.4 Communication and Technical Support Gaps

Challenge: Slow updates or unclear specs from suppliers.

Solution: U.S.-friendly account managers and technical support ensure clear, fast communication throughout the process.

With FromRubber, these challenges are addressed proactively, keeping your project on track.

7. How to Request a Quote or Sample from FromRubber

FromRubber simplifies the process of obtaining quotes or samples for custom rubber or silicone parts.

7.1 Step-by-Step Process

-

Prepare Your Design Details

- CAD drawings, sketches, or 3D models.

- Dimensions, tolerances, and surface finish requirements.

- Material choice (e.g., silicone, EPDM, nitrile).

- Expected quantity (small batch, bulk, or OEM production).

-

Include Application Details

- End-use environment (temperature, exposure to oils/chemicals, indoor/outdoor).

- Compliance needs (FDA, RoHS, REACH, medical-grade).

- Color and hardness preferences (Shore A rating).

-

Submit Your Request

- Email files and requirements to FromRubber’s sales team or use their quote request form.

- Request engineering support if unsure about materials or processes.

-

Typical Response Time

- Quote: Within 24–48 hours for standard parts.

- Samples: Prototypes produced in 7–10 business days, depending on complexity.

-

Review and Confirm

- Receive pricing, lead time, tooling costs, and shipping options.

- Approve the offer to proceed with prototyping or production.

For U.S. customers, FromRubber offers express shipping for samples to expedite testing, ensuring projects stay on schedule.

8. FAQs About Rubber Parts Manufacturing

8.1 What types of rubber materials are commonly used?

The most common materials include silicone (high heat resistance), natural rubber (elasticity), nitrile (oil resistance), EPDM (weather/UV resistance), and neoprene (balanced properties).

8.2 Which manufacturing process is best for my parts?

It depends on design, volume, and performance needs. Injection molding suits high-volume, precise parts; compression molding is cost-effective for lower runs; extrusion is ideal for continuous profiles.

8.3 Are your products certified for U.S. regulations?

Trusted manufacturers meet ISO 9001, RoHS, REACH, and FDA standards for food/medical-grade components. Always verify certifications before ordering.

8.4 What’s the typical MOQ (Minimum Order Quantity)?

MOQs vary by part size, complexity, and material. Many manufacturers offer low-volume prototyping before scaling to larger production runs.

8.5 How long is production and delivery?

Lead times typically range from 2–6 weeks after mold approval. Domestic U.S. orders arrive in days, while overseas shipments take longer.

8.6 Can I get a sample before placing a full order?

Yes, most suppliers provide samples for fit and quality checks to ensure parts meet specifications before mass production.Free Samles