Everything You Should Know About Custom Silicone Keypads

Have you ever paused to consider the humble keypad? It's an interface we interact with daily, from the remote control on our coffee table to the complex machinery on a factory floor. But did you know there's an entire universe of customization and engineering behind these surfaces, especially when it comes to silicone keypads? I'm here to guide you through everything you need to know about these incredibly versatile components.

In this comprehensive guide, we will dive deep into the fascinating world of custom silicone keypads. We'll explore their unique structural features, the various types available, and why they might just be the perfect, resilient solution for your next project.

Key Takeaways

- What They Are: Silicone keypads are durable, flexible interfaces made from elastomeric materials. They work by using a compressible webbing and a conductive element (like a carbon pill) to close a circuit on a printed circuit board (PCB) when a key is pressed.

- Core Benefits: They are highly resistant to water, dust, chemicals, and extreme temperatures, making them ideal for harsh environments. They offer excellent tactile feedback, are highly customizable in shape, color, and functionality, and are often more cost-effective for custom projects than other solutions.

- Types and Comparisons: Silicone keypads occupy a unique space between membrane switches (often less tactile and durable) and mechanical keyboards (more complex and expensive). They provide a sealed, robust alternative to both, and offer tangible benefits like glove-friendly operation over virtual (touchscreen) keypads.

- Customization is Key: Nearly every aspect of a silicone keypad can be tailored. This includes the physical layout, key shape and size, color, printed graphics, backlighting, and even the tactile "snap" feel of the keys.

- Manufacturing and Quality: The process involves compression molding of silicone, where design precision is crucial. Quality control is rigorous, involving life cycle testing for millions of actuations, environmental stress tests, and checks for material resistance to ensure long-term durability.

- Wide-Ranging Applications: You can find silicone keypads in everyday consumer electronics like TV remotes and kitchen appliances, as well as in critical industrial and medical devices, such as factory control panels and patient monitoring systems, where reliability and cleanliness are paramount.

Understanding the Fundamentals of a Silicone Keypad

To truly appreciate the value of a custom silicone keypad, it's essential to understand its basic construction and the inherent advantages it offers. These aren't just simple rubber buttons; they are engineered components designed for reliability and a superior user experience.

What is a Silicone Keypad?

At its core, a silicone keypad, also known as an elastomeric keypad, is a switching solution molded from a high-quality, silicone-based elastomer. It acts as a soft, flexible, and reliable interface between a user and an electronic device. Unlike a hard plastic keyboard, a silicone keypad is typically a single, continuous piece of molded material, which is key to many of its benefits.

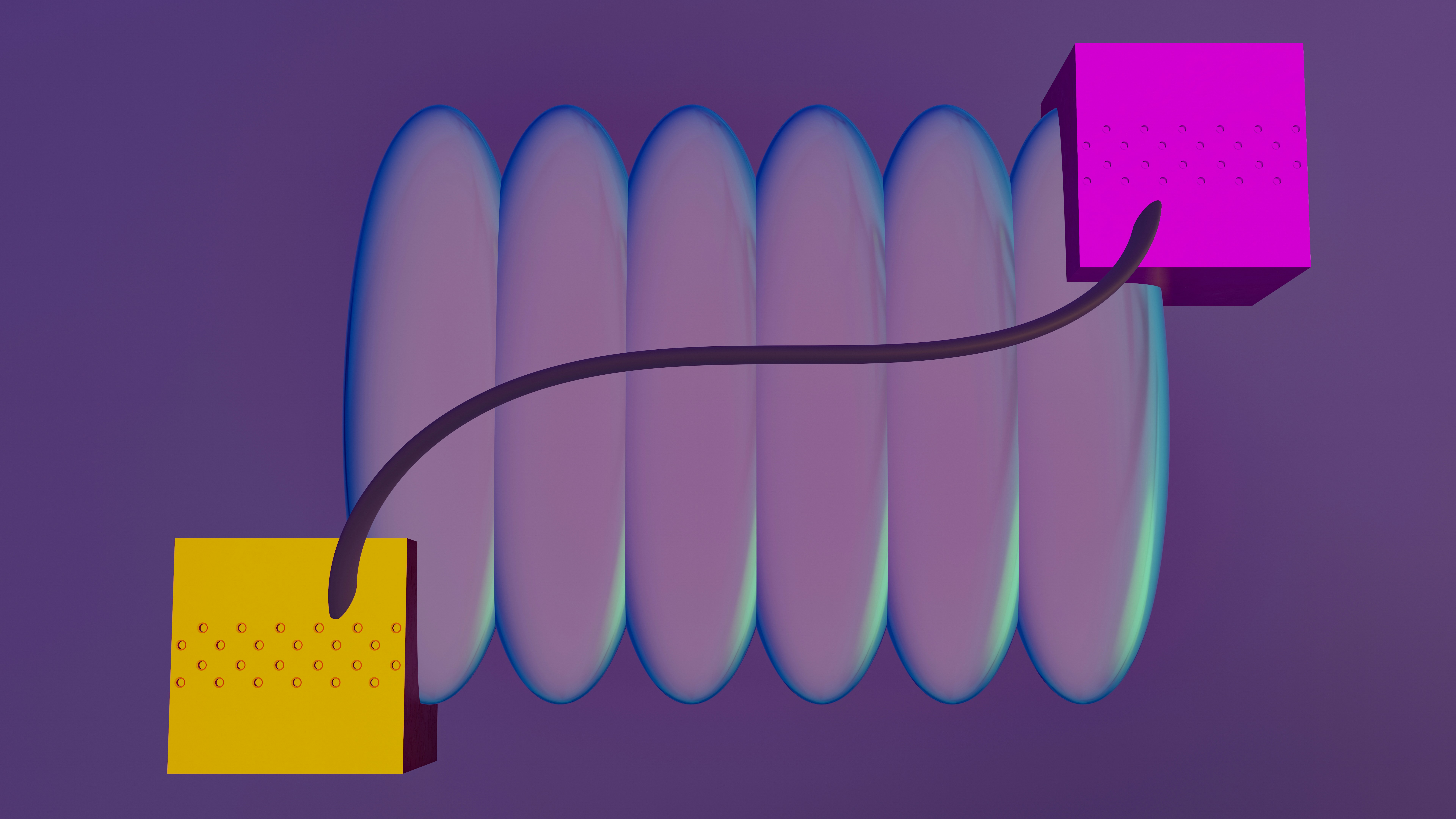

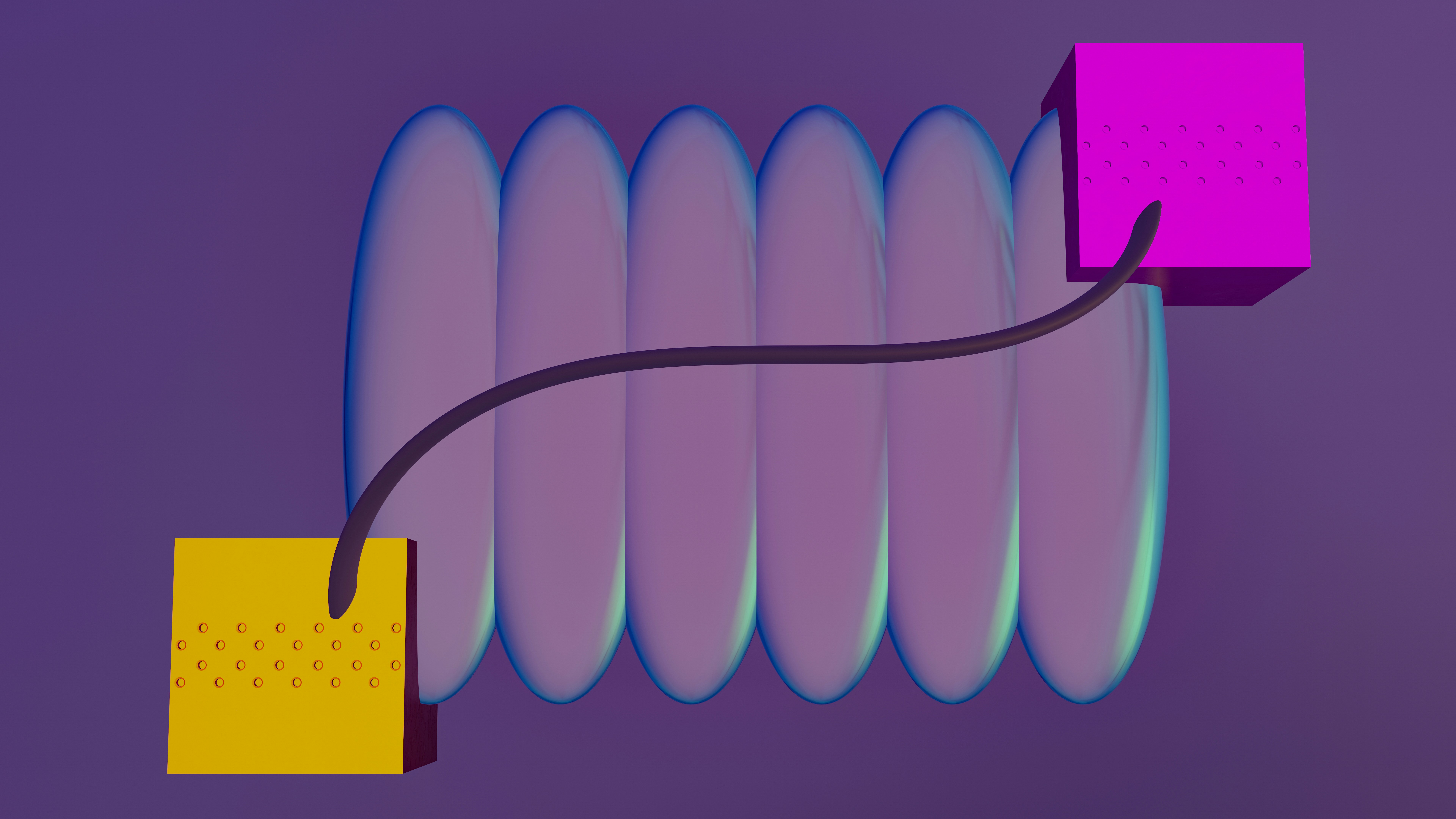

The fundamental technology relies on the compression and deformation of the silicone. Here’s a breakdown of its core components and how they work together:

- Silicone Webbing: The magic of a silicone keypad lies in the angled webbing designed around each key. This structure allows the key to deform uniformly when pressed and then "snap" back to its original position when released, providing distinct tactile feedback.

- Conductive Pill: On the underside of each key is a small, conductive element, most commonly a black "carbon pill". Gold or other conductive materials can also be used. Being an insulator by nature, the silicone itself doesn't conduct electricity. This pill is what bridges the electrical gap.

- Printed Circuit Board (PCB): Beneath the keypad lies a PCB with a set of exposed contacts under each key. When you press a key, the webbing deforms, allowing the conductive pill on the key's base to touch the contacts on the PCB. This momentary contact completes an electrical circuit, sending a signal to the device. Once you release the key, the silicone webbing returns to its neutral state, breaking the circuit.

This simple yet effective mechanism is what makes silicone keypads incredibly reliable and cost-effective, especially for custom designs.

The Benefits and Advantages of Silicone Keypads

Opting for a silicone keypad isn't just about a different feel; it's about leveraging a host of powerful advantages that other technologies struggle to match. Manufacturers and engineers choose them for their unique combination of durability, flexibility, and user-centric design.

Here are some of the most significant benefits:

- Exceptional Durability and Resistance: Silicone is a highly resilient material. Keypads made from it are naturally resistant to extreme temperatures, able to function in environments from -100°C to 250°C. They also withstand exposure to UV light, moisture, chemicals, and oils, making them perfect for outdoor, industrial, or medical applications.

- Water and Dust Proofing: Because silicone keypads are often molded as a single piece, they create a natural seal against the elements. This design prevents dust, dirt, and liquids from penetrating the device's internal electronics, often achieving high IP (Ingress Protection) ratings like IP66 or higher.

- Superior Tactile Feedback: The "snap" action of the silicone webbing provides clear, tangible feedback to the user, confirming that a keypress has been registered. This physical sensation can reduce input errors and is often preferred over the flat, non-responsive feel of membrane switches or touch screens.

- Design and Aesthetic Flexibility: Customization is where silicone keypads truly shine. They can be molded into virtually any shape, size, or color. This allows for multi-color keys, complex surface geometries, and unique ergonomic designs that would be prohibitively expensive with other methods.

- Cost-Effectiveness for Customization: While the initial tooling can be an investment, the per-piece cost for custom silicone keypads is relatively low, especially at volume. This makes them a more affordable option for bespoke designs compared to fully mechanical custom keyboards.

- Backlighting and Graphic Options: Silicone is an excellent light diffuser, making it ideal for backlighting with LEDs. Legends and graphics can be screen-printed onto the surface or, for a more durable and premium finish, laser-etched to allow light to shine through.

| Feature | Silicone Keypad | Membrane Switch | Mechanical Keyboard |

|---|---|---|---|

| Tactile Feedback | Excellent, customizable snap | Low to none | Excellent, varied by switch |

| Sealing | Excellent (Water/Dust Proof) | Good | Poor (unless specialized) |

| Durability | Very High (Chemical/Temp) | Moderate | High (but susceptible to liquids) |

| Customization | Very High (Shape, Color, Feel) | Moderate (Graphics only) | Moderate (Keycaps, Layout) |

| Cost (Custom) | Moderate | Low | High |

| Lifespan | High (millions of cycles) | Lower | Very High |

| Backlighting | Excellent and uniform | Possible, but less uniform | Excellent, per-key options |

Exploring Different Types of Silicone Keypads

The world of keypads is not one-size-fits-all. Different technologies offer distinct advantages, and understanding where silicone keypads fit in can help you make an informed decision for your product. They often serve as a perfect middle ground, blending the best features of other keypad types while adding their own unique benefits.

Membrane vs. Mechanical: Where Silicone Keypads Fit In

The two most common keypad technologies besides silicone are membrane and mechanical.

Membrane Keypads: These are constructed with multiple flexible layers. When you press a key area on the top layer, it pushes a conductive trace through a spacer hole to make contact with a trace on the bottom layer, completing a circuit.

- Pros: They are inexpensive to produce, can be very thin, and offer good sealing against contaminants.

- Cons: They typically offer poor to no tactile feedback, a "mushy" feel, and have a shorter operational lifespan compared to other technologies.

Mechanical Keyboards: These use individual, spring-loaded mechanical switches under each keycap. Each switch contains a housing, a stem, and a spring, and they provide a distinct, often audible "click" or tactile bump upon actuation.

- Pros: They offer excellent tactile feedback, extreme durability with lifespans of 50 million or more keypresses, and a high degree of user satisfaction for typing-intensive tasks.

- Cons: They are expensive, complex to manufacture, heavy, and are not naturally sealed against liquids or dust.

So, where do silicone keypads fit? Silicone keypads bridge the gap between these two extremes. They provide the excellent sealing and customization of a single molded part, similar to a membrane switch, but with far superior tactile feedback and durability. While a mechanical keyboard offers a sharper feel, a silicone keypad provides a satisfying snap and a much higher level of environmental protection at a lower cost, making it a more versatile option for rugged electronics.

Physical Keypads vs. Virtual Keypads: The Silicone Difference

With the rise of smartphones and tablets, virtual keypads (touchscreens) have become ubiquitous. They offer incredible flexibility, allowing the interface to change dynamically. However, they have significant drawbacks that highlight the advantages of a physical keypad, especially a silicone one.

- Tactile Feedback and Accuracy: The biggest advantage of a physical keypad is tactile feedback. Studies have shown that the physical sensation of a keypress improves typing speed and accuracy because users don't have to rely solely on visual confirmation. Touchscreens, being flat surfaces, have lower accuracy, especially in fast-paced or "eyes-free" operations.

- Use in Harsh Environments: In industrial, medical, or outdoor settings, users may be wearing gloves or have wet hands. Capacitive touchscreens often fail to register input under these conditions. A physical silicone keypad, which relies on mechanical pressure, works reliably every time.

- Durability and Reliability: While a touchscreen's glass can shatter on impact, a silicone keypad is naturally shock-resistant. The lack of moving parts and its sealed nature make it less prone to failure from dirt or liquid ingress compared to both touchscreens and some mechanical keyboards.

Hybrid solutions are becoming common, combining a touchscreen for dynamic information display with physical silicone buttons for critical, high-use functions like emergency stops or climate control.

Specialty Silicone Keypads for Unique Applications

The flexibility of silicone molding allows for a wide range of specialty keypads tailored to specific needs:

- Backlit Keypads: For use in low-light conditions, silicone keypads are ideal for backlighting.

- Laser-Etched Legends: A common technique involves spray-painting a translucent keypad with an opaque color, then using a laser to precisely etch away the paint from the key legends. This allows light from underlying LEDs to shine through only the characters, creating a crisp, clear, and extremely durable backlit effect.

- Light Guide Film (LGF): LGF is a thin layer that can be placed under the keypad to distribute light from just a few LEDs evenly across the entire interface, providing uniform illumination at a lower cost and power consumption.

- Coated and Sealed Keypads: For extra protection, keypads can be coated with materials like Polyurethane (PU) or epoxy. These coatings enhance resistance to abrasion from heavy use and protect the printed graphics from harsh chemicals or cleaning agents. This is crucial for medical devices that undergo frequent sterilization.

- Multi-Color Keypads: Through a process called flow molding, different colors of silicone can be integrated into a single keypad design, allowing for color-coded function keys without the need for painting.

- Non-Conductive Actuators: Some designs use a non-conductive silicone keypad that acts as an actuator for a different switch type underneath, such as a metal dome switch. This combines the comfortable feel and sealed surface of silicone with the distinct "click" and long life of a metal dome.

Customization Options for Your Silicone Keypad

One of the most compelling reasons to choose a silicone keypad is the nearly limitless scope for customization. Unlike rigid, standardized interfaces, every aspect of a silicone keypad can be engineered to meet the specific functional, ergonomic, and aesthetic requirements of your product. This allows you to create a user interface that is truly unique and perfectly optimized for its application.

Tailoring Silicone Keypad Layouts: QWERTY, Dvorak, and Beyond

While we are all familiar with the standard QWERTY layout on our computer keyboards, the true power of custom silicone keypads lies in their ability to break free from this convention. The layout of the keys—their size, shape, and placement—is one of the first and most critical design considerations. A well-designed layout can dramatically improve usability and reduce user error.

Here are some layout considerations:

- Application-Specific Design: For a medical device, the layout might prioritize large, clearly-labeled buttons for critical functions, spaced far apart to prevent accidental presses by a gloved hand. A complex industrial controller might require grouping keys by function, using different colors and shapes to guide the user intuitively.

- Ergonomic Layouts: For data-entry-heavy devices, designers can move beyond QWERTY to more ergonomic alternatives like Dvorak or Colemak. These layouts are designed to reduce finger travel and fatigue by placing the most frequently used keys on the home row. While this requires a learning curve, it can boost efficiency and user comfort in the long run.

- Non-Standard Form Factors: Silicone can be molded into curved or non-rectangular shapes, allowing the keypad to integrate seamlessly with the contours of your product. This is impossible with standard off-the-shelf keypads and is a key advantage for creating a polished, professional look.

Integrating Function Keys and Special Features into Your Silicone Keypad Design

Beyond the basic arrangement of keys, you can specify a huge range of special features to enhance functionality and user experience. The versatility of the silicone molding process makes it easy to integrate these features from the ground up.

Defining the Tactile Feel: The "feel" of a keypress is not accidental; it is a precisely engineered characteristic.

- Actuation Force: This is the amount of force (measured in grams) required to collapse the key's webbing. It can be designed to be very light (e.g., for rapid data entry) or heavy (e.g., for deliberate actions where accidental presses must be avoided).

- Snap Ratio: This crucial parameter defines the tactile feedback. It's a calculated ratio based on the force needed to press the key versus the force needed to hold it down. A snap ratio between 40% and 60% provides a satisfying "click" or "snap" feeling. A lower ratio results in a softer, less tactile feel but may increase the keypad's lifespan.

- Key Travel: The travel distance of a key can also be customized, typically ranging from 0.5 mm to 3.0 mm, to achieve the desired user experience.

Adding Visual and Functional Enhancements:

- Integrated Graphics and Legends: Text and symbols can be screen-printed onto the key surfaces. For maximum durability, a protective polyurethane (PU) or matte coating is often applied over the printing.

- Plastic or Metal Key Caps: For a different feel or enhanced durability, plastic or metal caps can be bonded to the top of the silicone keys. This can give the feel of a traditional hard key while retaining the sealed benefits of the silicone base.

- "Rocker" and Toggle Switches: A single molded key can be designed to act as a rocker switch, pivoting in the middle to actuate two different contacts (e.g., for volume up/down).

- Phosphorescent Additives: "Glow-in-the-dark" pigments can be added to the silicone, allowing the keys to be visible for a period of time after the lights go out an option useful in safety applications.

By working with an experienced manufacturer, you can combine these elements to create a fully integrated interface solution. This level of customization, from the core layout to the finest details of tactile response and visual aids, is what sets silicone keypads apart as a superior choice for innovative product design.

The Manufacturing Process of a Silicone Keypad

Transforming a concept into a tangible, high-quality silicone keypad involves a precise and multi-stage manufacturing process. Understanding these steps is crucial for designers and engineers to appreciate how their design choices impact the final product and to collaborate effectively with manufacturers. The journey from a digital file to a finished keypad is a blend of precision engineering, material science, and meticulous quality control.

From Concept to Creation: Designing Your Custom Silicone Keypad

The manufacturing process begins long before any silicone is molded. It starts with a collaborative design and engineering phase to ensure the final product meets all specifications.

- Design and Prototyping: The process starts with a design concept, often created using CAD (Computer-Aided Design) software. This initial design specifies the layout, dimensions, key shapes, and desired tactile response. Before committing to expensive production tooling, a prototype may be created to test and validate the design for ergonomics and functionality.

- Mold Making: Once the design is finalized, a high-precision mold is created. This tool, typically made from steel or aluminum using CNC milling or Electrical Discharge Machining (EDM), is the negative of the final keypad. The quality of the mold is paramount, as it dictates the dimensional accuracy, surface finish, and consistency of every keypad produced. The mold design itself is complex, incorporating elements that define key travel, webbing thickness, and venting systems to allow air to escape during molding.

- Material Preparation: The raw silicone rubber, which starts as a pliable, dough-like substance, is meticulously prepared. This involves mixing the base silicone with specific pigments to achieve the desired color, along with a curing agent that will cause it to harden under heat and pressure. Additives can also be blended in to achieve special properties.

- Compression Molding: This is the most common method for producing silicone keypads.

- Pre-weighed and shaped pieces of the prepared silicone material, known as "preforms," are carefully placed into the pre-heated mold cavities.

- The mold is closed, and a combination of immense pressure (often 100-200 tons) and high heat (typically 170°C to 200°C) is applied.

- This forces the silicone to liquefy and flow into every detail of the mold. The heat then triggers a chemical reaction called vulcanization or curing, which permanently cross-links the silicone molecules and solidifies the keypad into its final, elastomeric form.

- Post-Processing and Finishing: After curing, the keypads are removed from the mold. Any excess material, called "flash," is trimmed off. From here, they can undergo several finishing steps:

- Screen Printing or Laser Etching: Legends and graphics are applied to the key surfaces.

- Protective Coating: A PU or matte spray coating is often applied to protect the printing and enhance durability.

- Assembly: The finished keypad is then ready to be assembled with the PCB and other components of the final product.

For any project, working with an experienced manufacturer like fromrubber is crucial, as they can provide guidance on design for manufacturability and ensure a high-quality outcome.

Quality Control and Testing for Durable Silicone Keypads

To ensure that a silicone keypad can withstand years of use and harsh conditions, it must undergo a series of rigorous quality control tests. These tests validate everything from the keypad's mechanical durability to the resilience of its surface graphics.

Key quality control tests include:

- Life Cycle Testing: This is one of the most critical tests for durability. A machine repeatedly presses a key or set of keys to simulate real-world use. Keypads are often tested for hundreds of thousands or even millions of actuations to ensure the silicone webbing does not rupture and the tactile response remains consistent over the product's lifespan.

- Actuation Force Test: Specialized equipment is used to measure the exact force required to press each key. This test ensures that the tactile feedback is consistent across the entire keypad and meets the design specifications.

- Abrasion and Chemical Resistance Test: To verify the durability of printed legends and protective coatings, an abrasion test is performed. This often involves rubbing the surface with a cloth soaked in a substance like alcohol for thousands of cycles to simulate wear and cleaning. This ensures the graphics will not fade or rub off with use.

- Environmental Testing: Keypads are exposed to a range of temperatures and humidity levels to ensure they will not degrade or fail when used in extreme environments.

- Dimensional Inspection: Using tools like 3D measuring projectors, each batch of keypads is inspected to ensure all dimensions are within the strict tolerances defined in the design.

- Electrical Testing: The electrical resistance of the conductive carbon pills is tested to confirm it is within the acceptable range (typically under 100 Ohms) to guarantee a reliable switch closure.

By performing these extensive tests, manufacturers can guarantee that each custom silicone keypad delivered is not only visually perfect but also functionally robust and built to last.