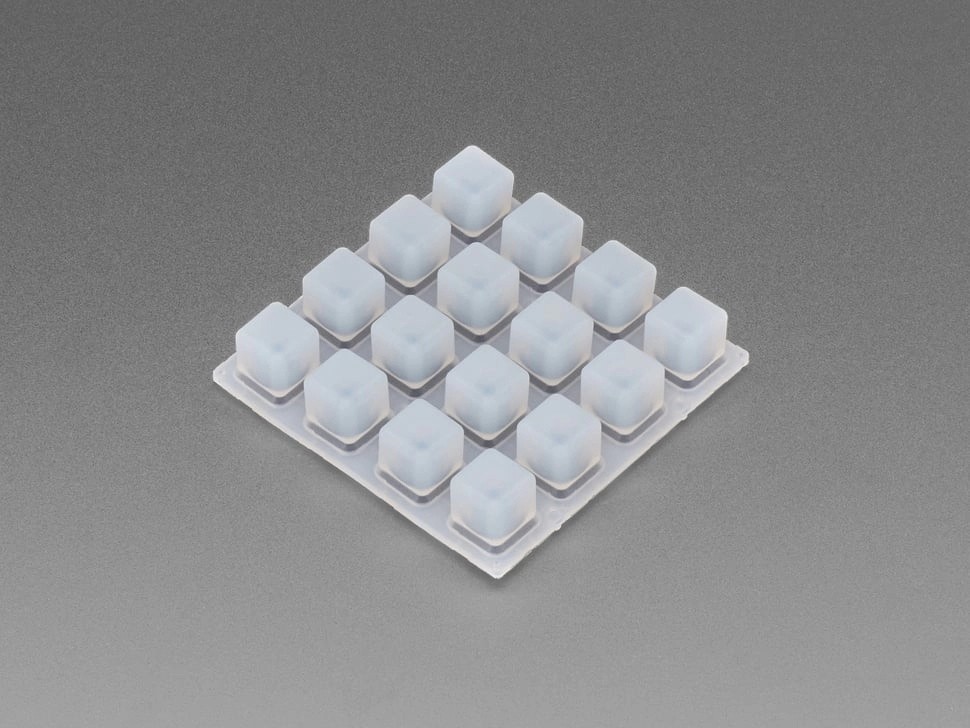

Silicone Conductive Buttons for MIDI Pad Controllers Durable Responsive

Silicone Conductive Buttons for MIDI Pad Controllers Silicone conductive buttons are flexible, touch-sensitive switches made from silicone rubber mixed with conductive materials like carbon or metal particles. This combination lets the button conduct electricity when pressed, completing an electrical circuit inside devices such as MIDI controllers. Unlike regular rubber buttons that just provide physical feedback, these buttons actively transmit signals, making them essential for electronic input. Silicone conductive buttons are flexible, touch-sensitive switches made from silicone rubber mixed with conductive materials like carbon or metal particles. This combination lets the button conduct electricity when pressed, completing an electrical circuit inside devices such as MIDI controllers. Unlike regular rubber buttons that just provide physical feedback, these buttons actively transmit signals, making them essential for electronic input. Here's how they work: when you press a silicone conductive button, the pressure compresses the silicone rubber, bringing the conductive particles closer together. This closes the circuit and sends an electrical signal to the MIDI controller's board. The pressure sensitivity allows for responsive performance, which is crucial when playing music or triggering sounds. Silicone conductive buttons are a top choice for MIDI pad controllers because they combine softness, flexibility, and durability. These buttons handle heavy use without wearing out quickly, making them perfect for musicians who rely on fast, repetitive playing. Compared to mechanical switches, silicone conductive buttons don't need heavy force and are quieter, essential for studio or live environments. Plastic buttons tend to be less responsive and can wear out quickly. Capacitive pads might feel too sensitive or unresponsive depending on the setup, but silicone buttons strike the right balance. These qualities make silicone conductive buttons the ideal solution for electronic music gear where durability, feel, and precision matter. Silicone conductive buttons for MIDI pad controllers come with clear technical standards to ensure reliable performance and musical precision. Below are the key specs and customization options commonly available: These options give musicians and manufacturers the ability to tailor silicone conductive buttons to specific MIDI controller needs, creating expressive, durable, and visually intuitive instruments. Silicone conductive buttons for MIDI pad controllers are mainly made using injection molding, a process that shapes silicone rubber infused with conductive materials into precise forms. This method ensures consistent button size and shape, which is key for reliability and a good tactile feel. Creating custom silicone rubber solutions allows manufacturers to tailor buttons to specific MIDI controller needs—whether it's adjusting firmness, shape, or electrical conductivity. However, getting the right balance of conductivity and touch response can be tricky. Small variations in the material or molding process can impact performance, so quality control is critical. FromRubber brings experience in custom silicone and plastic manufacturing designed specifically for MIDI controller buttons. Their expertise helps overcome challenges like maintaining uniform conductivity throughout the button and delivering durable, responsive keys that stand up to heavy use. This makes FromRubber a trusted source for durable silicone conductive switches built to fit music gear perfectly. Silicone conductive buttons are widely used in popular MIDI pad controllers because they offer the right mix of durability, responsiveness, and noise reduction. Brands like Akai and Novation often choose these buttons for their 4x4 button pads, allowing musicians to tap smoothly without that annoying click or mechanical noise. These pads deliver precise pressure sensitivity, which is essential for dynamic playing and music expression. In real-world cases, many electronic musicians and producers appreciate how these buttons hold up under heavy, repetitive use—making them a favorite in live performances and studio setups alike. FromRubber, for example, has worked on custom silicone buttons for several MIDI controller manufacturers, ensuring consistent tactile feel and electrical performance that matches each device's needs. Choosing the right silicone conductive buttons for your MIDI pad controller boils down to a few key factors. Here's what to focus on to get the best fit for your setup: By focusing on these aspects, you can select silicone conductive buttons that enhance your MIDI controller's performance and durability, making your music experience smoother and more expressive. Silicone conductive buttons in MIDI controllers can wear down over time, especially under heavy use. Here's how to spot problems and keep your device working smoothly. Silicone conductive buttons are evolving fast, and the future looks promising for MIDI pad controllers. Advances in silicone materials are making these buttons even more responsive and durable. New silicone compounds offer better conductivity with improved wear resistance, meaning your MIDI silicone controller buttons will last longer and feel more tactile than ever. Next-gen MIDI hardware and software are also driving innovation. Buttons are becoming smarter, integrating seamlessly with enhanced MIDI protocols that allow faster data transfer and more nuanced control. This means better precision and expression for musicians using a MIDI pad controller, especially in live settings or studio work. We're also seeing potential for adaptive conductive buttons. These smart buttons could change sensitivity or function on the fly, responding to different playing styles or software demands. Imagine a 4x4 button pad that learns your touch or switches modes automatically—this could open up new creative possibilities. Overall, expect custom silicone buttons for MIDI controllers to become more interactive and personalized, combining the best of material science and digital tech to elevate electronic music performance. No. High-quality silicone conductive buttons typically last 1–5 million+ presses while remaining completely silent — far superior for professional music applications. Yes. Most popular controllers (Akai MPC, Novation Launchpad, Ableton Push, etc.) use replaceable silicone pads that can be swapped in 10–30 minutes. Absolutely. The conductive carbon pill design provides excellent velocity and aftertouch response, often better than cheaper FSR sensors. Yes — they are nearly silent, perfect for late-night sessions or recording environments where mechanical click noise would be picked up. Yes. Full customization available: durometer 30A–70A, any Pantone color, translucent for RGB backlighting, and even printed logos. Discover custom silicone conductive buttons tailored for ultimate performance and durability. Click below to explore solutions from FromRubber and take your music to the next level! “We switched our entire new MIDI controller line to FromRubber’s custom silicone pads. The feel is incredible, aftertouch is perfectly consistent across all 64 pads, and we’ve had zero returns in 18 months of shipping.” “Our prototype had terrible velocity tracking and inconsistent pads. FromRubber delivered perfect 50A custom conductive silicone in just one revision. Fast sampling, excellent communication — exactly what a growing music-tech brand needs.”Table of Contents

1. What Are Silicone Conductive Buttons

2. Why Silicone Conductive Buttons Are Ideal for MIDI Pad Controllers

2.1 Key Benefits

Feature

Advantage for MIDI Controllers

Soft and Flexible

Comfortable feel, easy to press repeatedly without fatigue

Durable

Withstands intense use and won't crack or break easily

Precise Responsiveness

Accurate pressure sensing helps capture subtle musical expression

Low Noise

Quiet operation, unlike mechanical switches that can click loudly

Long Lifespan

Resist wear longer than plastic buttons or capacitive pads

3. Technical Specifications and Customization Options for Silicone Conductive Buttons MIDI Pad Controller

3.1 Electrical Conductivity and Performance

3.2 Sizes, Shapes, and Tactile Feedback

3.3 Color Coding for Performance

3.4 Integration with MIDI PCB and Housing

3.5 Environmental Resistance and Lifespan

Feature

Specification

Water Resistance

IPx5 or higher, splash-proof

Temperature Range

-20°C to 70°C (-4°F to 158°F)

Lifespan

1 million+ presses for durability

4. Manufacturing Process of Silicone Conductive Buttons

5. Use Cases and Examples in MIDI Pad Controllers

6. Tips for Selecting the Right Silicone Conductive Buttons for Your MIDI Controller

6.1 Electrical Specifications

6.2 Tactile Feel and Responsiveness

6.3 Durability for Intensive Use

6.4 Customization Options

6.5 Compatibility with Existing Controllers or New Designs

6.6 Working with Custom Manufacturers

7. Troubleshooting Common Issues with Silicone Conductive Buttons MIDI Pad Controllers

7.1 Signs of Wear and Tear

7.2 Preventing Wear

7.3 Electrical Failures and Maintenance Tips

7.4 When to Replace or Upgrade

8. Future Trends in MIDI Controller Button Technology

9. Frequently Asked Questions

1. Will silicone conductive buttons wear out faster than mechanical switches?

2. Can I replace the pads on my existing MIDI controller myself?

3. Do these buttons support velocity and polyphonic aftertouch properly?

4. Are silicone buttons quiet enough for studio recording?

5. Can I order custom colors, hardness, and backlighting compatibility?

Ready to Elevate Your MIDI Controller?

What Our Customers Say