Automotive Silicone Parts Benefits and Applications Guide

1. What Are Automotive Silicone Parts

Automotive silicone parts are components made from silicone rubber, a high-performance elastomer widely used in vehicles for its exceptional heat resistance, flexibility, and durability. Silicone is a synthetic polymer made primarily from silicon, oxygen, carbon, and hydrogen, engineered to maintain performance under extreme temperatures and harsh environmental conditions.

2. Common Types and Materials of Automotive Silicone Parts

2.1 Common Types of Automotive Silicone Parts

Silicone rubber automotive components are used in a wide range of applications, including:

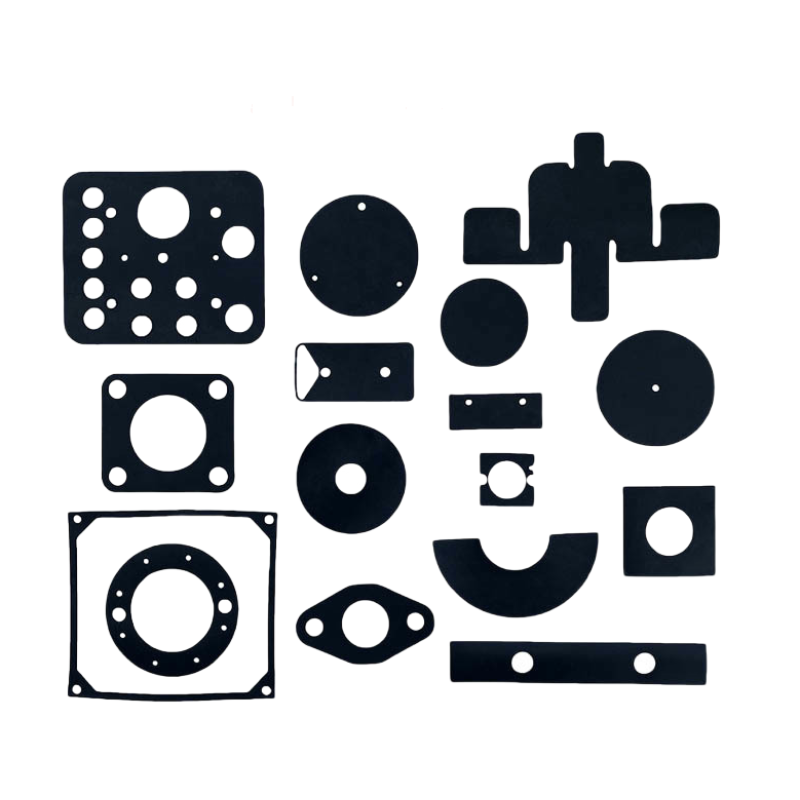

- Silicone gaskets and seals – Prevent fluid leaks in engines, transmissions, and other vehicle systems.

- Silicone hoses – Ideal for coolant, turbocharger, and heater applications thanks to their high-temperature tolerance.

- Silicone O-rings – Provide reliable sealing for fluid systems and withstand oils, fuels, and coolants.

- Vibration dampers – Reduce noise, vibration, and harshness (NVH) in critical areas.

- Automotive silicone trims and weather seals – Protect against moisture, dust, and UV exposure on doors, windows, and body panels.

2.2 Materials Used in Automotive Silicone Components

Silicone parts can be made from different grades of silicone rubber, each tailored for specific automotive needs:

- High-temperature silicone – Designed to handle continuous exposure to heat from engines or exhaust systems.

- FDA-grade silicone – Used in applications where food-grade or low-toxicity materials are required.

- Fluorosilicone – Offers enhanced resistance to fuels, oils, and aggressive chemicals.

- Custom silicone rubber compounds – Formulated for unique performance requirements, such as extreme cold flexibility or added flame resistance.

By combining advanced material properties with precise molding techniques—such as custom silicone injection molding and extrusion—manufacturers produce automotive silicone parts that meet rigorous industry standards and deliver long-lasting performance under real-life driving conditions.

3. Advantages of Using Silicone Parts in Automotive Applications

Automotive silicone parts are popular because they handle the toughest driving conditions without breaking down. Whether in scorching summers, freezing winters, or under the hood near a hot engine, silicone rubber automotive components keep their shape and performance. Their thermal resistance allows them to handle temperatures from well below freezing to over 400°F, making them ideal for both everyday cars and heavy-duty vehicles.

Silicone stands out for its flexibility and elasticity. It stays pliable even in extreme cold, which means custom silicone gaskets for cars, high-temperature silicone automotive seals, and O-rings can maintain tight seals without hardening or cracking over time. This helps keep engine and system performance consistent.

Another big advantage is chemical and weather resistance. Silicone holds up against automotive fluids such as oil, coolant, and transmission fluid, as well as environmental stress from UV, ozone, and road salts. That’s why both silicone hoses for automotive applications and silicone rubber vibration dampers in vehicles remain reliable for years.

With a long lifespan and low maintenance needs, silicone parts reduce replacement frequency and downtime—something U.S. customers value for cost savings and dependability. On top of that, quality silicone parts from trusted suppliers meet strict automotive industry safety and compliance standards, ensuring reliability for passenger cars, trucks, and specialty vehicles alike.

4. Key Applications of Silicone Parts in the Automotive Industry

Silicone rubber automotive components are used across almost every part of a vehicle because they can handle heat, pressure, and tough road conditions better than many other materials. Here are some of the most common uses:

4.1 Engine Components

Silicone parts like valve seals, gaskets, and O-rings are widely used in engines. High-temperature silicone automotive seals keep fluids from leaking and maintain engine performance even under constant heat and vibration.

4.2 Electrical Insulation and Protection

Silicone is an excellent electrical insulator. It’s used to protect wiring, connectors, and sensors from moisture, oil, and extreme temperatures. Custom silicone gaskets for cars also help shield sensitive automotive electronics from dust and vibration.

4.3 HVAC System Components

In heating, ventilation, and air conditioning systems, silicone hoses and seals resist cracking, hardening, and leaks caused by temperature swings. They’re essential for reliable climate control in both hot summers and cold winters.

4.4 Vibration and Noise Dampening

Silicone rubber vibration dampers reduce cabin noise and absorb engine or road vibrations. This helps make the ride smoother and quieter without adding a lot of weight to the vehicle.

4.5 Exterior and Interior Seals and Trims

From automotive silicone trim and seals on doors and windows to weatherstripping around sunroofs and trunks, silicone offers long-lasting resistance to UV rays, ozone, and changing weather, ensuring tight seals over the vehicle’s lifespan.

These applications show why many U.S. auto manufacturers and repair shops choose silicone rubber molding for automotive parts—it’s a proven solution for durability, safety, and performance.

5. Custom Solutions in Automotive Silicone Manufacturing by FromRubber

At FromRubber, we design and produce custom automotive silicone parts built to handle the demands of U.S. roads and climate conditions. Whether you need small-batch runs or large-scale production, we’ve got the tools and know-how to deliver high-quality parts that fit right the first time.

5.1 Our Capabilities

We handle the full range of silicone rubber manufacturing for automotive applications, including:

- Custom silicone molding – for seals, gaskets, O-rings, and trims made to exact fit.

- Silicone extrusion – perfect for continuous profiles like weatherstrips and door seals.

- Injection molding – high-volume, consistent parts with tight tolerances.

- Silicone overmolding – combining silicone with metal or plastic for hybrid automotive components.

5.2 Design and Prototyping

We work directly with your engineering team to create the right solution for your vehicle design. Our process includes:

- CAD-based design consultation.

- Rapid prototyping to test form and function before production.

- Tailored hardness, color, and finish options to match OEM or aftermarket needs.

5.3 Quality and Compliance

FromRubber follows strict automotive industry standards for material safety, durability, and environmental compliance. Every part goes through:

- Dimensional checks.

- Heat and chemical resistance testing.

- Fitment trials on real automotive assemblies.

5.4 Real-World Solutions

We’ve supplied high-temperature silicone automotive seals for turbocharged engines, custom silicone gaskets for EV battery housings, and silicone rubber vibration dampers for luxury interiors. Our experience covers everything from bulk wholesale molded silicone rubber automotive parts to niche custom molded silicone rubber automotive parts for specialty builds.

6. Choosing the Right Automotive Silicone Parts Manufacturer

Finding the right manufacturer for automotive silicone parts can make a big difference in performance, cost, and long-term reliability. In the U.S. market, customers expect consistent quality, fast turnaround, and the ability to handle custom designs. Here’s what to look for.

6.1 What to Look for in a Manufacturer

- Quality and Consistency – Use a manufacturer with proven quality control, ISO or IATF certifications, and experience in meeting strict automotive standards.

- Customization Capabilities – The ability to produce custom molded silicone rubber automotive parts, from unique gasket shapes to specialized high-temperature silicone automotive seals.

- Lead Times – Fast, dependable delivery schedules are critical to keeping production lines moving.

- Certifications – Compliance with automotive and safety regulations, including material traceability and performance testing.

- Scalability – Ability to handle both small runs for prototypes and large-scale bulk orders.

6.2 Why Work with FromRubber

FromRubber specializes in custom silicone gaskets for cars, precision silicone rubber molding for automotive parts, and custom silicone injection molding. We focus on:

- Innovation – Advanced compound formulations for heat, chemical, and weather resistance.

- Expertise – Decades of experience with engine seals, automotive silicone hoses, O-rings, and vibration dampers.

- Customer-Centric Service – U.S.-based design support, clear communication, and tailored production schedules to fit client needs.

6.3 Sustainability in Silicone Manufacturing

We also keep environmental considerations in mind by:

- Choosing low-waste molding techniques.

- Maximizing material efficiency to reduce scraps.

- Offering durable parts that last longer, cutting replacement waste.

FromRubber blends performance, customization, and responsible manufacturing—making it a dependable partner for OEMs and aftermarket suppliers across the U.S.

7. Future Trends in Automotive Silicone Parts

The role of automotive silicone parts is growing fast, especially as the industry shifts toward more advanced and eco-friendly vehicles. Here’s what’s driving the change:

7.1 Rising Use in Electric and Hybrid Vehicles

EVs and hybrids put more strain on certain components due to higher operating temperatures in batteries and electronics. High-temperature silicone automotive seals, gaskets, and insulation help protect these systems from heat, vibration, and chemical exposure. Silicone also resists cracking in cold climates, making it ideal for American regions with extreme weather swings.

7.2 Improved Silicone Compound Formulations

New blends of silicone rubber automotive components are delivering better heat resistance, flexibility, and life span. Manufacturers are now producing durable automotive silicone gaskets and hoses that can handle both higher pressure and more aggressive fluids—reducing the need for frequent replacements.

7.3 Lighter Weight for Better Fuel Efficiency

Silicone’s lighter weight compared to some traditional materials makes it perfect for lightweight automotive designs. Less weight means better fuel economy in combustion vehicles and longer range in EVs. Silicone rubber molding for automotive parts allows engineers to design complex shapes that keep parts strong but reduce bulk.

Key trends to watch:

- Growing demand for custom silicone gaskets for cars to fit new EV platforms.

- More bulk wholesale molded silicone rubber automotive parts for large-scale EV manufacturing.

- Integration of silicone rubber vibration dampers to make electric cars quieter inside.